Njengethuluzi elibalulekile ekukhiqizeni kwesimanje,Amathuluzi omshini we-CNCzidlala indima ebalulekile ekukhiqizweni kwezimboni ngenxa yokunemba nokusebenza kahle kwazo. Isifinyezo sethuluzi lomshini wokulawula idijithali, ongafinyelela ukucutshungulwa okuzenzakalelayo ngokufaka isistimu yokulawula uhlelo, futhi eyaziwa ngokuthi “ubuchopho” bamathuluzi omshini.

Lolu hlobo lwethuluzi lomshini lunezinzuzo eziningi ezibalulekile. Okokuqala, ukunemba komshini kuphezulu kakhulu, kuqinisekisa izinga elizinzile lemishini kanye nokufeza izindinganiso zokunemba eziphakeme kakhulu zezingxenye ezikhiqiziwe. Okwesibili, inekhono lokuxhumanisa izixhumanisi eziningi, ezingacubungula izingxenye ezinokwakheka okuyinkimbinkimbi futhi ihlangabezane nezidingo zokucubungula zezakhiwo ezahlukahlukene eziyinkimbinkimbi. Lapho kudingeka izinguquko ezingxenyeni zomshini, ukushintsha nje uhlelo lwe-CNC konga kakhulu isikhathi sokulungiselela ukukhiqiza futhi kuthuthukisa ukusebenza kahle kokukhiqiza. Ngesikhathi esifanayo, ithuluzi lomshini ngokwalo linokunemba okuphezulu nokuqina, futhi amanani okucubungula avumayo angakhethwa. Ukukhiqiza kuvame ukuba izikhathi ezi-3 kuye kwezi-5 kunamathuluzi omshini ajwayelekile. Ngaphezu kwalokho, amathuluzi omshini anezinga eliphezulu lokuzenzakalela, elinganciphisa umfutho wabasebenzi futhi lenze inqubo yokukhiqiza ibe lula futhi isebenze kahle.

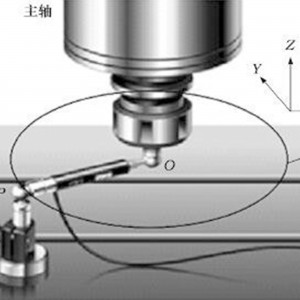

Nokho, ukusebenza kanye nokuqaphaAmathuluzi omshini we-CNCzidinga izinga eliphezulu lama-opharetha, futhi izidingo zobuchwepheshe zabasebenzi bokulungisa ziqine nakakhulu.Amathuluzi omshini we-CNCngokuvamile aqukethe izingxenye ezimbalwa ezibalulekile. Umsingathi ungumzimba oyinhloko kaIthuluzi lomshini we-CNC, okuhlanganisa umzimba womshini, ikholomu, ukuphotha, indlela yokuphakelayo nezinye izakhi zomshini, futhi kuwukhiye wokuqedela izinqubo zokusika ezihlukahlukene. Idivayisi ye-CNC iwumgogodla we-Ithuluzi lomshini we-CNC, okuhlanganisa ihadiwe nesofthiwe ehambisanayo, enesibopho sokufaka izinhlelo zengxenye yedijithali, nokuqedela ukugcinwa kolwazi, ukuguqulwa kwedatha, imisebenzi yokuhumusha, nemisebenzi ehlukahlukene yokulawula. Idivayisi yokushayela iyingxenye yokushayela yendlela yokwenza, okuhlanganisa iyunithi ye-spindle drive, iyunithi yokuphakelayo, i-spindle motor, kanye ne-feed motor. Ngaphansi kokulawula kwe-Idivayisi ye-CNC, idrayivu yokuphotha nokuphakelayo ifinyelelwa ngohlelo lwe-servo lukagesi noma lwe-electro-hydraulic, olwenza ithuluzi lomshini likwazi ukuqedela imisebenzi yomshini ehlukahlukene njengokumisa, imigqa eqondile, amajika ahleliwe, namajika wendawo. Amadivayisi asizayo nawo abalulekile, njengokupholisa, ukususwa kwe-chip, ukugcoba, ukukhanyisa, ukuqapha kanye namanye amadivaysi, kanye namadivayisi asebenza ngamandla kanye ne-pneumatic, amadivaysi okukhipha ama-chip, ama-workbench okushintshana, ama-CNC turntables namakhanda ezinkomba ze-CNC, kanye namathuluzi okusika kanye namadivayisi okuqapha nokuhlonza, ahlanganisa ndawonye aqinisekisa ukusebenza okuvamile kwamathuluzi omshini wokulawula idijithali. Ngaphezu kwalokho, ukuhlela kanye nezinye izinto ezisizayo zingasetshenziselwa ukuhlela ingxenye nokugcinwa ngaphandle komshini.

Naphezu kwezinzuzo eziningi zeAmathuluzi omshini we-CNC, amaphutha okunemba komshini avame ukuhlangana nawo phakathi nenqubo yokukhiqiza. Lolu hlobo lwephutha lunezici zokufihla okuqinile kanye nobunzima obukhulu bokuxilonga. Izizathu eziyinhloko zokungasebenzi kahle okunjalo yilezi ezilandelayo. Okokuqala, iyunithi yokuphakelayo yethuluzi lomshini ingashintshwa noma ishintshwe, ngaleyo ndlela kuthinte ukunemba komshini. Okwesibili, i-zero offset engavamile ye-eksisi ngayinye yethuluzi lomshini futhi ingaholela ezinkingeni ngokunemba komshini. Ukuhlehla okungavamile kwemvume kusiqondiso se-axial nakho kungaba nemiphumela emibi ekunembeni komshini. Ngaphezu kwalokho, isimo esingavamile sokusebenza kwenjini, okuwukuthi amaphutha ezingxenyeni zikagesi nezilawulayo, futhi esinye sezizathu ezibalulekile zokunemba komshini okungavamile. Okokugcina, ukuthuthukiswa kwezinhlelo zemishini, ukukhethwa kwamathuluzi okusika, kanye nezici zobuntu kungase kube izici eziholela ekunembeni komshini okungavamile.

Ekukhiqizeni kwangempela, ukunemba komshini okungavamile kweAmathuluzi omshini we-CNCkungase kubangele ukulahlekelwa okukhulu emabhizinisini. Lawa maphutha awathinti kuphela ikhwalithi yomkhiqizo, kodwa angase futhi aholele ekubambezelekeni kokukhiqiza, izindleko ezikhuphukile, nezinye izinkinga. Ngakho-ke, ukuxilongwa ngesikhathi kanye nokuxazululwa kwalawa maphutha kubalulekile. Kodwa-ke, ngenxa yokufihla kanye nobunzima bokuxilonga amaphutha anjalo, ukukhomba ngokunembile imbangela yephutha akuwona umsebenzi olula. Lokhu kudinga abasebenzi bezokulungisa ukuthi babe nolwazi olucebile, amakhono asezingeni eliphezulu, kanye nokuqonda okujulileIthuluzi lomshini we-CNCizinhlelo.

Ukuze kubhekwane nalezi zinselele, amabhizinisi kudingeka aqinise ukuqeqeshwa kwabasebenzi abanakekela izinyawo, bathuthukise izinga labo lobuchwepheshe kanye nekhono lokuhlola amaphutha. Ngasikhathi sinye, amabhizinisi kufanele futhi asungule ukuxilongwa okuzwakalayo kwephutha kanye nendlela yokusingatha, ukuze akwazi ukuthatha izinyathelo ngokushesha futhi anciphise ukulahlekelwa lapho kwenzeka amaphutha. Ngaphezu kwalokho, ukugcinwa njalo nokugcinwa kwamathuluzi omshini we-CNC nakho kungenye yezinyathelo ezibalulekile zokuvimbela amaphutha ukuthi enzeka. Ngokuhlola, ukuhlanza, nokulungisa izingxenye ezihlukahlukene zethuluzi lomshini, izinkinga ezingaba khona zingabonakala ngesikhathi, futhi izinyathelo ezihambisanayo zingathathwa ukuzixazulula, ngaleyo ndlela kuqinisekiswe ukusebenza okuvamile kanye nokunemba komshini wethuluzi lomshini.

Ngokuthuthuka okuqhubekayo kobuchwepheshe,Amathuluzi omshini we-CNCnazo zihlale zithuthukiswa futhi zithuthukiswa. Ubuchwepheshe obusha kanye nemisebenzi ihlala ivela, iletha amathuba amasha nezinselele ekuthuthukisweni kwemboni yokukhiqiza. Isibonelo, ukusetshenziswa kobuchwepheshe obuhlakaniphile kwenzaAmathuluzi omshini we-CNCukwenza imishini ngokuhlakaniphe kakhulu, ukulungisa ngokuzenzakalelayo amapharamitha wemishini, futhi uthuthukise ukusebenza kahle kwemishini kanye nekhwalithi. Ngesikhathi esifanayo, ukusetshenziswa kwedatha enkulu kanye nobuchwepheshe bekhompuyutha yamafu nakho kunikeza izindlela ezintsha zokuqapha okukude kanye nokuxilongwa kwamaphutha amathuluzi omshini we-CNC, okuvumela amabhizinisi ukuba aqonde ngesikhathi esengeziwe isimo sokusebenza kwamathuluzi omshini futhi abone izingozi ezingaba khona zamaphutha kusenesikhathi.

Ngamafuphi, amathuluzi omshini we-CNC, njengokwesekwa okubalulekile kwezobuchwepheshe kokukhiqizwa kwesimanje, adlala indima engenakuthathelwa indawo ekukhuthazeni ukuthuthukiswa kwemboni yokukhiqiza. Naphezu kokuhlangabezana nokungasebenzi kahle nezinselele ezihlukahlukene phakathi nenqubo yokukhiqiza, sikholelwa ukuthi ngokusungula izinto ezintsha zobuchwepheshe eziqhubekayo kanye nezindlela zokuphatha zokulondoloza ezithuthukisiwe, amathuluzi omshini we-CNC azoqhubeka nokuba negalelo elikhulu ekuthuthukisweni kwemboni yokukhiqiza, ukuyisiza ukuba ifinyelele izinga eliphezulu nokusebenza kahle.

Millingmachine@tajane.comLeli ikheli lama le-imeyili. Uma uyidinga, ungangithumelela i-imeyili. Ngilinde incwadi yakho eseShayina.