Esigabeni semboni yokukhiqiza yanamuhla, amathuluzi omshini we-CNC asephenduke umgogodla wokukhiqiza ngamakhono awo okucubungula asebenzayo nanembile. Izidingo zokunemba komshini zezingxenye ezibalulekile zamathuluzi omshini we-CNC ngokungangabazeki ziyizici ezibalulekile ezinquma ukukhethwa kwezinga lokunemba amathuluzi omshini we-CNC.

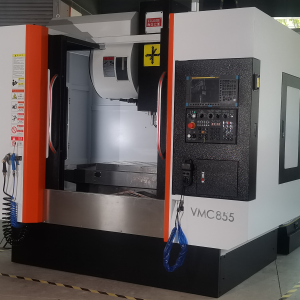

Amathuluzi omshini we-CNC ahlukaniswa ngezigaba ezihlukene njengokulula, ukusebenza ngokugcwele, nokunemba okuphezulu ngenxa yokusetshenziswa kwawo okuhlukahlukene, futhi amazinga okunemba kwawo ahluka kakhulu. Amathuluzi omshini we-CNC olula asabambe indawo emkhakheni wamanje wamalebula nemishini yokugaya, enokulungiswa okulinganiselwe kokunyakaza okungu-0.01mm, nokunemba kokunyakaza nomshini ngokuvamile kusuka ku-0.03 kuya ku-0.05 mm noma ngaphezulu. Nakuba ukunemba kulinganiselwe, kwezinye izimo zemishini lapho izimfuneko zokunemba zingaqinile ngokwedlulele, amathuluzi omshini we-CNC alula adlala indima engenakuthathelwa indawo ngenxa yezinzuzo zawo zezomnotho nokusebenza okulula.

Ngokuphambene kakhulu, amathuluzi omshini we-CNC anembe kakhulu adizayinelwe izidingo ezikhethekile zokwenza imishini, ngokunemba kokumangazayo okungu-0.001mm noma ngaphansi. Amathuluzi omshini we-CNC anembe kakhulu avame ukusetshenziswa emikhakheni enembayo nesezingeni eliphezulu njenge-aerospace nemishini yezokwelapha, ehlinzeka ngosekelo oluqinile lobuchwepheshe lokukhiqiza izingxenye eziyinkimbinkimbi kakhulu nezifuna ukunemba.

Ngokombono wokunemba, amathuluzi omshini we-CNC angaphinde ahlukaniswe abe izinhlobo ezijwayelekile nezinembayo. Ngokuvamile, kunezinto zokuhlola ukunemba ezingama-20 kuye kwezingama-30 zamathuluzi omshini we-CNC, kodwa okubaluleke kakhulu futhi okumele ukunemba kokuma kwe-eksisi eyodwa, ukunemba kokuma okuphindaphindiwe kwe-eksisi eyodwa, nokuzungeza kwesiqephu sokuhlola esikhiqizwe izimbazo zomshini ezimbili noma ngaphezulu ezixhumene.

Ukunemba kokuma kanye nokunemba kokuma okuphindaphindiwe kuyaphelelisana futhi ndawonye kuveza iphrofayela yokunemba ephelele yezingxenye ezihambayo ze-eksisi yethuluzi lomshini. Ikakhulukazi mayelana nokunemba kokubeka ngokuphindaphindiwe, kufana nesibuko, sibonisa ngokucacile ukuzinza kokuma kwe-axis kunoma iyiphi indawo yokuma ngaphakathi kwe-stroke yayo. Lesi sici siba yisisekelo sokulinganisa ukuthi i-shaft ingasebenza ngokuzinzile nangokwethembekile, futhi ibalulekile ekuqinisekiseni ukusebenza okuzinzile kwesikhathi eside kwethuluzi lomshini kanye nokuvumelana kwekhwalithi yomshini.

Isofthiwe yesistimu ye-CNC yanamuhla ifana nengcweti ehlakaniphile, enemisebenzi ecebile nehlukahlukene yesinxephezelo samaphutha, ekwazi ukunxephezela ngobuhlakani amaphutha esistimu akhiqizwe kusixhumanisi ngasinye seketango lokudlulisa okuphakelayo ngokunembile nangokuzinzile. Uma sithatha izixhumanisi ezihlukahlukene zochungechunge lokudlulisela njengesibonelo, izinguquko ezicini ezifana nokucaciswa, ukuguquguquka okunwebekayo, nokuqina kokuxhumana akuhlali njalo, kodwa kubonisa izinguquko eziguquguqukayo ezisheshayo neziguquguqukayo ezifana nobukhulu bomthwalo webhentshi lomsebenzi, ubude bebanga lokunyakaza, kanye nesivinini sokuma kokunyakaza.

Kwamanye amasistimu e-servo e-open-loop kanye ne-semi-close-loop feed servo, izingxenye zomshini zokushayela ngemva kwezingxenye zokulinganisa zifana nemikhumbi eya phambili emoyeni nasemvuleni, kuncike ezintweni ezihlukahlukene zengozi. Isibonelo, isenzeko sokwelulwa okushisayo kwezikulufu zebhola kungabangela ukukhukhuleka endaweni yangempela yokuma yebhentshi lokusebenza, ngaleyo ndlela kulethe amaphutha abalulekile angahleliwe ekunembeni komshini. Kafushane, uma kukhona ukukhetha okuhle enqubweni yokukhetha, akungabazeki ukuthi okokusebenza okunemba okuhle kakhulu okuphindaphindwayo kufanele kubekwe phambili, kwenezela umshwalense oqinile kukhwalithi yokucubungula.

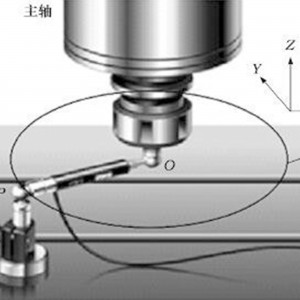

Ukunemba kobuso obuyisilinda bokugaya noma imigqa eyisipesheli egayiwe (imicu), njengerula elihle lokulinganisa ukusebenza kwethuluzi lomshini, inkomba eyinhloko yokuhlola ngokujulile izici ezinyakazayo ze-servo ze-eksisi ye-CNC (ama-eksisi amabili noma amathathu) kanye nomsebenzi wokuhumusha wethuluzi lomshini we-CNC. Indlela ephumelelayo yokunquma le nkomba ukukala ukuzungeza kwendawo eyisilinda ecutshunguliwe.

Emsebenzini wokusika izingcezu zokuhlola kumathuluzi omshini we-CNC, indlela yomshini wokugaya i-oblique oblique enezinhlangothi ezine iphinde ibonise inani layo eliyingqayizivele, elingahlulela ngokunembile ukusebenza okunembayo kwezimbazo ezimbili ezilawulekayo ekunyakazeni kwe-interpolation eqondile. Lapho wenza lo msebenzi wokusika isilingo, kuyadingeka ukuthi ufake ngokucophelela isigayo esisetshenziselwa umshini oqondile emshinini wokuphotha, bese wenza ukugaya ngokucophelela esibonelweni esiyindilinga esibekwe ebhentshini lokusebenza. Ngamathuluzi omshini omncane nosayizi omaphakathi, usayizi wesifanekiso esiyindilinga ngokuvamile ukhethwa phakathi kuka-¥ 200 no-¥ 300. Lobu bubanzi buhlolwe ngokwenza futhi bungahlola ngempumelelo ukunemba komshini kwethuluzi lomshini.

Ngemva kokuqeda ukugaya, beka ngokucophelela isifanekiso esisikiwe kumitha eyindingilizi futhi ulinganise ukuzungeza kwendawo yayo eyenziwe ngomshini usebenzisa ithuluzi lokulinganisa elinembayo. Kule nqubo, kuyadingeka ukubheka nokuhlaziya imiphumela yokulinganisa ngokuzwela. Uma kukhona amaphethini wokudlidliza we-milling cutter endaweni eyisilinda egayiwe, iyasixwayisa ukuthi isivinini sokuhumusha sethuluzi lomshini singase singazinzi; Uma ukuzungeza okukhiqizwa ukugaya kubonisa amaphutha asobala we-elliptical, ngokuvamile kubonisa ukuthi ukuzuza kwezinhlelo ezimbili ze-eksisi ezilawulekayo ekuhambeni kokuhumusha akuzange kufaniswe kahle; Lapho kukhona izimpawu zokumisa endaweni ngayinye elawulayo yokuguqula isiqondiso sokunyakaza kwe-eksisi endaweni eyindilinga (okungukuthi, ekuhambeni okuqhubekayo kokusika, ukumisa ukunyakaza kokuphakelayo endaweni ethile kuzokwakha ingxenye encane yezimpawu zokusika zensimbi endaweni yomshini), lokhu kusho ukuthi imvume eya phambili nokuhlehlayo ye-eksisi ayikalungiswanga ibe sesimweni esifanele.

Umqondo wokunemba kokuma kwe-eksisi eyodwa ubhekisela ebangeni lephutha elikhiqizwa lapho kumiswa noma yiliphi iphuzu ngaphakathi kwe-stroke ye-eksisi. Kufana nendlu yesibani, ekhanyisa ngokuqondile ikhono lokunemba kwemishini yethuluzi lomshini, futhi ngaleyo ndlela ngokungangabazeki iba esinye sezinkomba zobuchwepheshe ezibucayi kakhulu zamathuluzi omshini we-CNC.

Okwamanje, kunomehluko othile kumithethonqubo, izincazelo, izindlela zokulinganisa, nezindlela zokucubungula idatha zokunemba kokuma kwe-eksisi eyodwa phakathi kwamazwe emhlabeni jikelele. Esethulweni sedatha yesampula yethuluzi lomshini we-CNC ehlukahlukene, izindinganiso ezivamile nezicashunwe kabanzi zihlanganisa i-American Standard (NAS), izindinganiso ezinconyiwe yi-American Machine Tool Manufacturers Association, German Standard (VDI), Japanese Standard (JIS), International Organization for Standardization (ISO), kanye ne-Chinese National Standard (GB).

Phakathi kwalezi zindinganiso ezimangalisayo, izindinganiso zaseJapane zithambile ngokwemithethonqubo. Indlela yokulinganisa isuselwe kusethi eyodwa yedatha ezinzile, bese isebenzisa amanani ngobuhlakani ± ukucindezela inani lephutha ngesigamu. Njengomphumela, ukunemba kokuma okutholwe kusetshenziswa izindlela zokulinganisa ezijwayelekile zase-Japan kuvame ukuhluka ngokuphindwe kabili uma kuqhathaniswa namanye amazinga.

Nakuba amanye amazinga ehluka endleleni acubungula ngayo idatha, agxilile enhlabathini yezibalo zamaphutha ukuze ahlaziye futhi alinganise ukunemba kokuma. Ngokukhethekile, ngephutha lephoyinti lokuma elithile ku-axis elawulekayo yethuluzi lomshini we-CNC, kufanele ikwazi ukukhombisa amaphutha okungenzeka angenzeka phakathi nezinkulungwane zezikhathi zokuma phakathi nokusetshenziswa kwesikhathi eside kwethuluzi lomshini esikhathini esizayo. Nokho, kunqunyelwe izimo zangempela, ngokuvamile singakwazi ukwenza inani elilinganiselwe lemisebenzi phakathi nokulinganisa, ngokuvamile izikhathi ezi-5 kuye kwezingu-7.

Ukwahlulela okunembayo kwamathuluzi omshini we-CNC kufana nohambo oluyinselele lokuxazulula iphazili, alufinyelelwanga ngobusuku obubodwa. Ezinye izinkomba zokunemba zidinga ukuhlolwa ngokucophelela nokuhlaziywa kwemikhiqizo ecutshunguliwe ngemuva kokusebenza kwangempela komshini wethuluzi lomshini, ngokungangabazeki okwandisa ubunzima nobunzima bokwahlulela ngokunemba.

Ukuze siqinisekise ukukhethwa kwamathuluzi omshini we-CNC ahlangabezana nezidingo zokukhiqiza, sidinga ukuhlola ngokujulile imingcele yokunemba kwamathuluzi omshini futhi senze ukuhlaziya okuphelele nokunemininingwane ngaphambi kokwenza izinqumo zokuthenga. Ngesikhathi esifanayo, kubalulekile ukuba nokuxhumana okwanele nokujulile kanye nokushintshisana nabakhiqizi bamathuluzi omshini we-CNC. Ukuqonda ileveli yenqubo yokukhiqiza yomkhiqizi, ukuqina kwezinyathelo zokulawula ikhwalithi, kanye nokuphelela kwesevisi yangemva kokuthengisa kunganikeza isisekelo esibalulekile sokuthatha izinqumo.

Ezimweni ezisebenzayo zohlelo lokusebenza, uhlobo kanye nezinga lokunemba lamathuluzi omshini we-CNC kufanele futhi kukhethwe ngokwesayensi nangokunengqondo ngokusekelwe emisebenzini ethile yokwenza imishini kanye nezidingo zokunemba zezingxenye. Ezingxenyeni ezinezidingo zokunemba okuphezulu kakhulu, amathuluzi omshini afakwe amasistimu e-CNC athuthukile kanye nezingxenye ezinemba okuphezulu kufanele acatshangelwe kuqala ngaphandle kokungabaza. Lokhu kukhetha akuqinisekisi kuphela ikhwalithi yokucubungula enhle kakhulu, kodwa futhi kuthuthukisa ukusebenza kahle kokukhiqiza, kunciphisa amazinga e-scrap, futhi kuletha izinzuzo eziphezulu zezomnotho ebhizinisini.

Ukwengeza, ukuhlolwa okunembayo okuvamile nokugcinwa ngokucophelela kwamathuluzi omshini we-CNC kuyizinyathelo ezibalulekile zokuqinisekisa ukusebenza okuzinzile kwesikhathi eside nokugcina amakhono omshini wokunemba okuphezulu. Ngokukhomba ngokushesha nokuxazulula izinkinga ezingase zibe nokunemba, impilo yesevisi yamathuluzi omshini inganwetshwa ngempumelelo, kuqinisekiswe ukuzinza nokuthembeka kwekhwalithi yokwenza imishini. Njengokunakekela imoto yomjaho eyigugu, ukunaka okuqhubekayo kuphela nokunakekelwa okungayigcina isebenza kahle emzileni.

Kafushane, ukunemba kwamathuluzi omshini we-CNC kuyinkomba yokucabangela enezinhlangothi eziningi futhi ebanzi, esebenza kuyo yonke inqubo yokuklama nokuthuthukiswa kwamathuluzi omshini, ukukhiqiza nokuhlanganisa, ukufakwa nokulungisa iphutha, kanye nokusetshenziswa nokugcinwa kwansuku zonke. Kuphela ngokuqonda okuphelele nokubazi kahle ulwazi olufanele nobuchwepheshe singakwazi ukukhetha ngokuhlakanipha ithuluzi lomshini we-CNC elifaneleka kakhulu emisebenzini yangempela yokukhiqiza, singene ngokugcwele ekusebenzeni kahle okungase kube khona, futhi sifake amandla aqinile nokusekelwa ekuthuthukisweni okunamandla kwemboni yokukhiqiza.