Emkhakheni wokucutshungulwa kwemishini yesimanje, imishini yokumba kanye nemishini yokugaya ye-CNC iyimishini emibili evamile futhi ebalulekile yamathuluzi omshini, anomehluko omkhulu emisebenzini, izakhiwo, kanye nezimo zohlelo lokusebenza. Ukuze sikunikeze ukuqonda okujulile nokuphelele kwalezi zinhlobo ezimbili zamathuluzi omshini, umkhiqizi womshini wokugaya we-CNC uzokunikeza incazelo enemininingwane ngezansi.

1. Ukuqhathanisa okuqinile

Izici eziqinile zemishini yokumba

Umshini wokubhoboza uklanyelwe kakhulu ukumelana namandla amakhulu aqondile, anamandla amancane asemaceleni. Lokhu kungenxa yokuthi indlela eyinhloko yokucubungula yomshini wokubhoboza iwukubhoboza, futhi i-drill bit ngokuyinhloko ibhoboza eduze nokuqondisa okuqondile ngesikhathi sokusebenza, futhi amandla asetshenziswa ku-workpiece agxile kakhulu ku-axial direction. Ngakho-ke, isakhiwo somshini wokumba siye saqiniswa endaweni eqondile ukuze kuqinisekiswe ukuzinza, ukunciphisa ukudlidliza nokuphambuka phakathi nenqubo yokumba.

Kodwa-ke, ngenxa yekhono elibuthakathaka lemishini yokumba ukuze imelane namandla asemaceleni, lokhu kuphinde kukhawulele ukusetshenziswa kwayo kwezinye izimo eziyinkimbinkimbi zomshini. Uma kudingekile ukwenza i-side machining ku-workpiece noma lapho kukhona ukuphazamiseka okuphawulekayo kwe-lateral phakathi nenqubo yokumba, umshini wokubhoboza ungase ungakwazi ukuqinisekisa ukunemba komshini nokuzinza.

Izidingo eziqinile zemishini yokugaya ye-CNC

Ngokungafani nemishini yokumba, imishini yokugaya ye-CNC idinga ukuqina okuhle ngoba amandla akhiqizwa ngesikhathi sokugaya ayinkimbinkimbi kakhulu. Amandla okugaya awafaki nje amandla amakhulu aqondile, kodwa futhi adinga ukumelana namandla amakhulu aseceleni. Phakathi nenqubo yokugaya, indawo yokuxhumana phakathi komsiki wokugaya kanye nendawo yokusebenza inkulu, futhi ithuluzi liyazungeza ngenkathi lisika ngendlela evundlile, okuholela ekutheni amandla okugaya asebenze ngezindlela eziningi.

Ukuze ubhekane nezimo zengcindezi eziyinkimbinkimbi kangaka, ukwakheka kwesakhiwo semishini yokugaya ye-CNC kuvame ukuba namandla futhi kuzinzile. Izingxenye ezibalulekile zethuluzi lomshini, njengombhede, amakholomu, nezinsimbi zomhlahlandlela, zenziwe ngezinto ezisezingeni eliphezulu nezakhiwo ezithuthukisiwe ukuze kuthuthukiswe ukusebenza kokuqina nokusebenza kokumelana nokudlidliza. Ukuqina okuhle kwenza imishini yokugaya ye-CNC igcine ukunemba okuphezulu ngenkathi imelana namandla amakhulu okusika, iyenze ifaneleke ukucubungula ubujamo obuhlukahlukene obuyinkimbinkimbi kanye nezingxenye ezinemba kakhulu.

2.Ukwehluka kwesakhiwo

Izici zesakhiwo semishini yokumba

Isakhiwo somshini wokubhoboza silula, futhi ezimweni eziningi, inqobo nje uma okuphakelayo okuqondile kufinyelelwa, kungahlangabezana nezidingo zokucubungula. Umshini wokubhoboza uvamise ukuba nomzimba wombhede, ikholomu, ibhokisi lokuphotha, ibhentshi lokusebenza, nendlela yokuphakelayo.

Umbhede uyingxenye eyisisekelo yomshini wokumba, osetshenziselwa ukusekela nokufaka ezinye izingxenye. Ikholomu igxilile embhedeni ukuze inikeze ukusekela kwebhokisi le-ekseli eliyinhloko. Ibhokisi lokuphotha lifakwe i-spindle kanye nendlela yejubane eguquguqukayo, esetshenziselwa ukushayela ukujikeleza kwebhithi yokubhoboza. Ibhentshi lokusebenzela lisetshenziselwa ukubeka izinto zokusebenza futhi lingalungiswa kalula futhi libekwe endaweni. I-feed mechanism inesibopho sokulawula ukunyakaza kwe-axial feed ye-drill bit ukuze kuzuzwe ukulawula ukujula kokumba.

Ngenxa yendlela yokucubungula elula yemishini yokumba, isakhiwo sabo silula futhi izindleko zabo ziphansi. Kodwa lesi sakhiwo esilula siphinde sinciphise ukusebenza nokucubungula uhla lomshini wokumba.

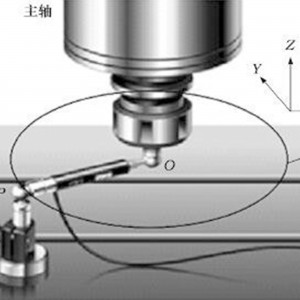

Ukwakheka kwesakhiwo semishini yokugaya ye-CNC

Isakhiwo semishini yokugaya ye-CNC siyinkimbinkimbi kakhulu. Ayidingi nje kuphela ukufeza ukuphakela okuqondile, kodwa okubaluleke kakhulu, idinga nokuba nemisebenzi yokuphakelayo evundlile kanye ne-transverse. Imishini yokugaya ye-CNC imvamisa yakhiwa izingxenye ezinjengombhede, ikholomu, itafula lokusebenzela, isihlalo sehhashi, ibhokisi lokuphotha, uhlelo lwe-CNC, uhlelo lwe-feed drive, njll.

Umbhede nekholomu kunikeza isakhiwo esizinzile sokusekela sethuluzi lomshini. Ibhentshi lomsebenzi lingahamba libheke phezulu ukuze lifinyelele ukuphakela kwe-lateral. Isihlalo sehhashi sifakwe kukholomu futhi singashayela ibhokisi lokuphotha ukuze lihambe libheke phezulu, lithole ukuphakela kwe-longitudinal. Ibhokisi lokuphotha lifakwe ama-spindles asebenza kahle kakhulu kanye namadivayisi anembile okudlulisa isivinini aguquguqukayo ukuze ahlangabezane nezidingo zamasu ahlukene okucubungula.

Uhlelo lwe-CNC luyingxenye eyinhloko yokulawula yomshini wokugaya we-CNC, onesibopho sokuthola imiyalelo yokuhlela futhi iguqule ibe amasignali okulawula ukunyakaza kwe-eksisi ngayinye yethuluzi lomshini, ukufeza izenzo zomshini ezinembile. Isistimu ye-feed drive iguqula imiyalelo yesistimu ye-CNC ibe ukunyakaza kwangempela kwethebula lokusebenza nesihlalo sehhashi ngokusebenzisa izingxenye ezifana nezinjini nezikulufu, okuqinisekisa ukunemba komshini kanye nekhwalithi yendawo.

3.Ukucubungula umsebenzi

Amandla okucubungula omshini wokumba

Umshini wokubhoboza uyisisetshenziswa esisebenzisa i-drill bit ukubhola nokucubungula ama-workpieces. Ngaphansi kwezimo ezijwayelekile, ukujikeleza kwe-drill bit ukunyakaza okuyinhloko, kuyilapho ukunyakaza kwe-axial yomshini wokubhoboza kuwukunyakaza kokuphakelayo. Imishini yokumba ingenza ngembobo, imbobo eyimpumputhe kanye neminye imisebenzi yomshini kuma-workpieces, futhi ingahlangabezana nezidingo zokuvula nokunemba okuhlukile ngokushintsha izingcezu zokubhoboza ezinobubanzi obuhlukahlukene nezinhlobo.

Ngaphezu kwalokho, umshini wokubhoboza ungenza futhi imisebenzi elula yokumba nokuthinta. Kodwa-ke, ngenxa yemikhawulo yayo yesakhiwo nokusebenza, imishini yokumba ayikwazi ukwenza umshini wokwakheka okuyinkimbinkimbi ebusweni bezinto zokusebenza, njengendawo eyisicaba, ama-grooves, amagiya, njll.

Ububanzi bemishini yemishini yokugaya ye-CNC

Imishini yokugaya ye-CNC inohlu olubanzi lwamakhono okucubungula. Ingasebenzisa abasiki bokugaya ukuze bacubungule indawo eyisicaba yezinto zokusebenza, kanye nokwakheka okuyinkimbinkimbi njengemifantu namagiya. Ngaphezu kwalokho, imishini yokugaya ye-CNC ingaphinda icubungule izingcezu zokusebenza ezinamaphrofayili ayinkimbinkimbi, njengezindawo ezigobile kanye nezindawo ezingajwayelekile, ngokusebenzisa amathuluzi okusika akhethekile nezindlela zokuhlela.

Uma kuqhathaniswa nemishini yokumba, imishini yokugaya ye-CNC inokusebenza kahle okuphezulu kwemishini, isivinini esisheshayo, futhi ingafinyelela ukunemba okuphezulu kwemishini kanye nekhwalithi ephezulu. Lokhu kwenze imishini yokugaya ye-CNC isetshenziswe kabanzi emikhakheni efana nokukhiqiza isikhunta, i-aerospace, kanye nezingxenye zezimoto.

4.Amathuluzi nezakhiwo

Amathuluzi nezinsiza zemishini yokumba

Ithuluzi eliyinhloko elisetshenziswa emshinini wokubhoboza i-drill bit, futhi ukuma nobukhulu be-drill bit kuyakhethwa ngokuvumelana nezidingo zokucubungula. Enqubweni yokumba, izinto ezilula ezifana namapliers, ama-V-blocks, njll. ngokuvamile zisetshenziselwa ukubeka nokubopha ucezu lokusebenza. Ngenxa yokuthi amandla acutshungulwa umshini wokubhoboza ngokuyinhloko agxile ekuqondeni kwe-axial, ukuklanywa kwe-fixture kulula, ikakhulukazi ukuqinisekisa ukuthi umsebenzi wokusebenza ngeke unyakaze noma ujikeleze ngesikhathi sokumba.

Amathuluzi nezakhiwo zemishini yokugaya ye-CNC

Kunezinhlobo ezahlukene zamathuluzi okusika asetshenziswa emishinini yokugaya ye-CNC, okuhlanganisa izigayo zokuphela kwebhola, izigayo zokugcina, izigayo zobuso, njll. ngaphezu kwabasiki abavamile bokugaya. Izinhlobo ezahlukene zamathuluzi okusika zifanele amasu okucubungula ahlukene kanye nezidingo zomumo. Emshinini wokugaya we-CNC, izidingo zokuklama ze-fixtures ziphakeme, futhi izici ezifana nokusatshalaliswa kwamandla okusika, ukunemba kokuma kwendawo yokusebenza, kanye nobukhulu bamandla okubamba kufanele kucatshangelwe ukuze kuqinisekiswe ukuthi ucezu lokusebenza aluzwani nokugudluzwa kanye nokuguqulwa ngesikhathi senqubo yomshini.

Ukuze kuthuthukiswe ukusebenza kahle kwemishini nokunemba, imishini yokugaya ye-CNC ivamise ukusebenzisa izinto ezikhethekile nezilungiswayo, njengezinto ezihlanganisiwe, izinto ezisebenza ngogesi, njll. Ngesikhathi esifanayo, imishini yokugaya ye-CNC nayo ingafinyelela ukushintsha okusheshayo kwamathuluzi okusika ahlukene ngokusebenzisa amadivaysi okushintsha ithuluzi elizenzakalelayo, ngokuqhubekayo ukuthuthukisa ukuguquguquka nokusebenza kahle kokucubungula.

5. Izinhlelo kanye nokusebenza

Ukuhlela nokusebenza kwemishini yokumba

Ukuhlelwa komshini wokubhoboza kulula, ngokuvamile kudinga kuphela ukusethwa kwemingcele njengokujula kokubhola, isivinini, kanye nezinga lokuphakela. Ama-opharetha angaqedela inqubo yokwenza imishini ngokusebenzisa ngesandla isibambo noma inkinobho yethuluzi lomshini, futhi bangasebenzisa isistimu ye-CNC elula yokuhlela nokulawula.

Ngenxa yobuchwepheshe obulula bokucubungula bemishini yokumba, ukusebenza kulula, futhi izidingo zobuchwepheshe zabaqhubi ziphansi kakhulu. Kodwa lokhu futhi kunciphisa ukusetshenziswa kwemishini yokumba ekucubunguleni ingxenye eyinkimbinkimbi.

Ukuhlela nokusebenza kwemishini yokugaya ye-CNC

Ukuhlelwa kwemishini yokugaya ye-CNC kuyinkimbinkimbi kakhulu, kudinga ukusetshenziswa kwesofthiwe yokuhlela echwepheshile efana ne-MasterCAM, i-UG, njll., ukuze kukhiqizwe izinhlelo zokwenza imishini ezisekelwe emidwebeni kanye nezidingo zomshini zezingxenye. Phakathi nenqubo yokuhlela, izici eziningi ezifana nendlela yamathuluzi, imingcele yokusika, nokulandelana kwenqubo kudingeka kucatshangelwe ukuze kuqinisekiswe ukunemba nokusebenza kahle kwemishini.

Mayelana nokusebenza, imishini yokugaya ye-CNC ivamise ukuhlonyiswa ngezikrini zokuthinta noma amaphaneli okusebenza. Ama-opharetha adinga ukujwayelana nesixhumi esibonakalayo kanye nemisebenzi yohlelo lwe-CNC, bakwazi ukufaka ngokunembile imiyalelo namapharamitha, futhi baqaphe isimo phakathi nenqubo yokwenza imishini. Ngenxa yobuchwepheshe bokucubungula obuyinkimbinkimbi bemishini yokugaya ye-CNC, kunesidingo esikhulu sezinga lobuchwepheshe nolwazi lochwepheshe lwabaqhubi, okudinga ukuqeqeshwa okukhethekile nokuzijwayeza ukuze uphumelele kahle.

6. Inkambu yohlelo lokusebenza

Izimo zokusetshenziswa kwemishini yokumba

Ngenxa yesakhiwo sayo esilula, izindleko eziphansi, nokusebenza okulula, imishini yokumba isetshenziswa kakhulu kwezinye izinkundla zokucobelelana ngolwazi ezincane zemishini, izinkundla zokucobelelana ngolwazi zokulungisa, kanye nemizi yokucubungula ngayinye. Isetshenziselwa ikakhulukazi ukucubungula izingxenye ezinezakhiwo ezilula kanye nezidingo zokunemba okuphansi, njengezingxenye zohlobo lwembobo, izingxenye zokuxhuma, njll.

Kwamanye amabhizinisi okukhiqiza ngobuningi, imishini yokumba ingase isetshenziselwe ukucubungula izinqubo ezilula, njengokumba izimbobo eshidini lensimbi. Kodwa-ke, ukuze kucutshungulwe izingxenye ezinokwakheka okuphezulu neziyinkimbinkimbi, imishini yokumba ayikwazi ukuhlangabezana nezidingo.

Ububanzi bokusetshenziswa kwemishini yokugaya ye-CNC

Imishini yokugaya ye-CNC isetshenziswe kabanzi emikhakheni efana nokukhiqiza isikhunta, i-aerospace, izingxenye zezimoto, imishini ye-elekthronikhi, njll. ngenxa yezinzuzo zabo zokunemba okuphezulu kwemishini, ukusebenza kahle okuphezulu, nemisebenzi enamandla. Ingasetshenziselwa ukucubungula isikhunta esiyinkimbinkimbi esihlukahlukene, izingxenye ezinembayo, izingxenye zebhokisi, njll., futhi ingahlangabezana nezidingo zokukhiqiza zesimanje zokucubungula okunembayo nokusebenza okuphezulu.

Ikakhulukazi kwezinye izimboni zokukhiqiza ezisezingeni eliphezulu, imishini yokugaya ye-CNC isiphenduke imishini ebalulekile, idlala indima ebalulekile ekuthuthukiseni ikhwalithi yomkhiqizo, ukunciphisa imijikelezo yokukhiqiza, kanye nokunciphisa izindleko.

7, Ukuqhathanisa izibonelo machining

Ukuze ubonise ngokunembile umehluko emiphumeleni yemishini phakathi kwemishini yokumba kanye nemishini yokugaya ye-CNC, izibonelo ezimbili ezikhethekile zomshini zizoqhathaniswa ngezansi.

Isibonelo 1: Ukukhanda ingxenye yepuleti le-orifice elilula

Ukucutshungulwa komshini wokubhoboza: Okokuqala, lungisa i-workpiece ebhentshini lokusebenzela, khetha i-drill bit efanelekile, lungisa ukujula kokubhoboza kanye nezinga lokuphakela, bese uqala umshini wokubhoboza wokucubungula ukumba. Ngenxa yokuthi imishini yokumba ingenza kuphela ukumba okuqondile, izidingo zokunemba kwesikhundla sembobo kanye nekhwalithi yobuso azikho phezulu, futhi ukusebenza kahle kokucubungula kuphansi kakhulu.

Ukucutshungulwa komshini wokugaya we-CNC: Uma usebenzisa umshini wokugaya we-CNC ukuze ucutshungulwe, isinyathelo sokuqala ukwenza imodeli yezingxenye ku-3D futhi ukhiqize uhlelo lomshini ngokuya ngezidingo zenqubo yokwenza. Bese ufaka ucezu lokusebenza endaweni ezinikele, faka uhlelo lomshini ngohlelo lwe-CNC, bese uqala ithuluzi lomshini lokwenza imishini. Imishini yokugaya ye-CNC ingakwazi ukufeza ukusebenza ngesikhathi esisodwa kwezimbobo eziningi ngokusebenzisa uhlelo, futhi ingaqinisekisa ukunemba kwesikhundla kanye nekhwalithi ephezulu yemigodi, ithuthukise kakhulu ukusebenza kahle kwemishini.

Isibonelo sesi-2: Ukucubungula ingxenye yesikhunta esiyinkimbinkimbi

Ukucutshungulwa komshini wokumba: Ezingxenyeni zesikhunta ezinokwakheka okuyinkimbinkimbi, imishini yokumba icishe ingakwazi ukuqedela imisebenzi yokucubungula. Ngisho noma icutshungulwa ngezindlela ezithile ezikhethekile, kunzima ukuqinisekisa ukunemba kwemishini kanye nekhwalithi ephezulu.

Ukucutshungulwa komshini wokugaya we-CNC: Ngokusebenzisa imisebenzi enamandla yemishini yokugaya ye-CNC, kungenzeka ukuthi uqale wenze umshini onzima ezingxenyeni zesikhunta, ukhiphe okuningi okweqile, bese wenza ukunemba okuncane nokunemba, ekugcineni uthole izingxenye zesikhunta ezinembayo nezisezingeni eliphezulu. Phakathi nenqubo yomshini, izinhlobo ezahlukene zamathuluzi zingasetshenziswa futhi imingcele yokusika ingenziwa elungiselelwe ukuthuthukisa ukusebenza kahle kwemishini kanye nekhwalithi ephezulu.

Ngokuqhathanisa lezi zibonelo ezimbili ezingenhla, kungabonakala ukuthi imishini yokumba ifanele ukucubungula imbobo elula, kuyilapho imishini yokugaya i-CNC ikwazi ukucubungula ubujamo obuhlukahlukene obuyinkimbinkimbi kanye nezingxenye ezinembile kakhulu.

8, Isifinyezo

Kafushane, kunomehluko omkhulu phakathi kwemishini yokumba kanye nemishini yokugaya ye-CNC ngokuya ngokuqina, ukwakheka, imisebenzi yokucubungula, ukulungiswa kwamathuluzi, imisebenzi yokuhlela, nezinkambu zohlelo lokusebenza. Umshini wokubhoboza unesakhiwo esilula kanye nezindleko eziphansi, futhi ufanelekile ukubhoboza okulula nokucubungula umgodi wokukhulisa; Imishini yokugaya ye-CNC inezici zokunemba okuphezulu, ukusebenza kahle okuphezulu, nokusebenza okuningi, okungahlangabezana nezidingo zokukhiqiza zesimanje zokucubungula ingxenye eyinkimbinkimbi.

Ekukhiqizeni kwangempela, imishini yokumba noma imishini yokugaya ye-CNC kufanele ikhethwe ngokunengqondo ngokusekelwe emisebenzini ethile yokucubungula kanye nezidingo zokufeza umphumela omuhle kakhulu wokucubungula kanye nezinzuzo zezomnotho. Ngesikhathi esifanayo, ngenqubekelaphambili eqhubekayo yobuchwepheshe kanye nokuthuthukiswa kwemboni yokukhiqiza, imishini yokumba kanye nemishini yokugaya ye-CNC nayo ihlala ithuthuka futhi iphelelisa, ihlinzeka ngosekelo oluqinile lwezobuchwepheshe ekuthuthukisweni kwemboni yokucubungula imishini.