Emkhakheni wokukhiqiza izimboni zesimanje, impo imishini isikhungoiyithuluzi elibalulekile. Inikeza ukwesekwa okuqinile kokucutshungulwa kwama-workpiece ahlukahlukene ngokusebenza kwawo okuyingqayizivele kanye nokusetshenziswa okubanzi.

I. Imisebenzi esemqoka yesikhungo somshini esiqondile

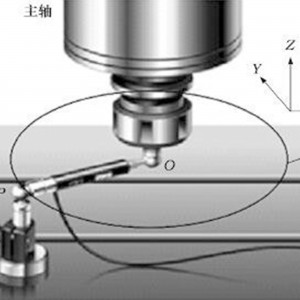

Umsebenzi wokugaya

Impo imishini isikhungoingaqedela kahle kakhulu imisebenzi yezindiza zokugaya, imifantu nezindawo, futhi ingacubungula imigodi eyinkimbinkimbi namaqhubu. Ngethuluzi lokugaya elifakwe ku-spindle, ngaphansi kokulawulwa okunembile kohlelo lomshini, lisebenzisana nebhentshi lokusebenzela elihamba libheke ezimbazoni ezintathu zokuxhumanisa u-X, Y kanye no-Z ukuze kuzuzwe ukubunjwa okunembile kwendawo yokusebenza ukuze ihlangabezane nezinga elidingwa umdwebo.

Umsebenzi wokulawula iphuzu

Umsebenzi wayo wokulawula amaphuzu uhloselwe ikakhulukazi ukucubungula imbobo ye-workpiece, ehlanganisa imisebenzi ehlukahlukene yokucubungula imbobo njengokubeka isikhungo sokumba, ukubhoboza, ukubuyisela kabusha, ukusakaza, ukuhinya nokubhoboza, ukuhlinzeka ngesisombululo esisebenzayo sokucutshungulwa kwembobo ye-workpiece.

Umsebenzi wokulawula oqhubekayo

Ngosizo lwe-linear interpolation, i-arc interpolation noma ukunyakaza kwe-curve eyinkimbinkimbi, i-mpo imishini isikhungoingagaya futhi icubungule indiza kanye nezindawo ezigobile ze-workpiece ukuze ibone izidingo zokucubungula zobumo obuyinkimbinkimbi.

Umsebenzi wokunxephezela irediyasi yethuluzi

Lo msebenzi ubaluleke kakhulu. Uma uhlela ngokuqondile ngokomugqa wekhonta womsebenzi, ikhonsathi yangempela izoba inani elikhulu lerediyasi yethuluzi lapho udweba ikhonsathi engaphakathi, kanye nenani elincane lerediyasi yethuluzi lapho udweba ikhontoyutha yangaphandle. Ngesinxephezelo serediyasi yamathuluzi, isistimu yokulawula izinombolo ngokuzenzakalelayo ibala umzila omaphakathi wethuluzi, ochezuka enanini lendawo yethuluzi lekhonsayutha yocezu lokusebenza, ukuze kucutshungulwe ngokunembile ikhonsathi ehlangabezana nezimfuneko. Ngaphezu kwalokho, lo msebenzi ungaphinda unxephezele ukuguga kwamathuluzi kanye namaphutha omshini ukuze kubonakale inguquko esuka emshinini onzima ukuya ekuqedeni.

Umsebenzi wesinxephezelo sobude bethuluzi

Ukushintsha inani lesinxephezelo sobude bethuluzi akukwazi kuphela ukunxephezela inani lokuchezuka kobude bethuluzi ngemva kokuba ithuluzi lishintshiwe, kodwa futhi kulawula ukuma kwendiza yenqubo yokusika ukuze kulawulwe ngokuphumelelayo ukunemba kokuma kwe-axial kwethuluzi.

Umsebenzi wokucubungula umjikelezo ongaguquki

Ukusetshenziswa kweziqondiso zokucubungula umjikelezo ogxilile kwenza uhlelo lokucubungula lube lula kakhulu, kunciphisa umthwalo wokuhlela, futhi kuthuthukisa ukusebenza kahle kokucubungula.

Umsebenzi wohlelo olungaphansi

Ezingxenyeni ezinomumo ofanayo noma ofanayo, zibhalwa njenge-subroutine futhi zibizwa ngohlelo oluyinhloko, olungenza lula kakhulu ukwakheka kohlelo. Le modularization yohlelo ihlukaniswe ngamamojula ahlukene ngokuya ngenqubo yenqubo yokucubungula futhi ibhalwe kuhlelo oluncane, bese kuthiwa uhlelo oluyinhloko ukuqedela ukucutshungulwa kwe-workpiece, okwenza uhlelo lube lula ukulucubungula nokulungisa iphutha, futhi luphinde lube lula ekwandiseni inqubo yokucubungula.

Umsebenzi okhethekile

Ngokumisa isofthiwe yokukopisha kanye nedivayisi yokukopisha, ukuskena nokuqoqwa kwedatha yezinto ezibonakalayo kuhlanganiswe nezinzwa, izinhlelo ze-NC zikhiqizwa ngokuzenzakalelayo ngemva kokucutshungulwa kwedatha ukuze kubonakale ukukopishwa nokuhlehliswa kokucubungula kwezinto zokusebenza. Ngemva kokumisa isofthiwe ethile ne-hardware, umsebenzi wokusetshenziswa wesikhungo somshini esime mpo uye wandiswa ngokwengeziwe.

II. Ukucutshungulwa kobubanzi besikhungo somshini esime mpo

Ukucutshungulwa kwendawo

Kubandakanya ukugaya kwendiza evundlile (XY), indiza eqondile (XZ) kanye nendiza eseceleni (YZ) yocezu lokusebenza. Udinga kuphela ukusebenzisa isikhungo semishini eqondile esinama-eksisi amabili kanye nesigamu esilawulwa uhafu ukuze uqedele imisebenzi yokugaya yalezi zindiza.

Ukucutshungulwa kwendawo

Ukuze kugaywe izindawo eziyinkimbinkimbi ezigobile, isikhungo somshini esima mpo esixhunywe ku-shaft esinama-eksisi amathathu noma ngaphezulu siyadingeka ukuze kuhlangatshezwane nokunemba okuphezulu komshini kanye nezidingo zomumo.

III. Izisetshenziswa zesikhungo sokukhanda esiqondile

Umbambi

I-universal fixture ikakhulukazi ihlanganisa izidladla zomlomo oyisicaba, izinkomishi zokumunca kazibuthe kanye nemishini yamapuleti okucindezela. Kuma-workpieces amaphakathi, amakhulu noma ayinkimbinkimbi, izinto ezihlanganisiwe zidinga ukuklanywa. Uma kusetshenziswa izinto ze-pneumatic kanye ne-hydraulic futhi ukulayishwa nokulayishwa okuzenzakalelayo kwenziwa ngokulawulwa kohlelo, kuzothuthukisa kakhulu ukusebenza kahle komsebenzi futhi kunciphise umfutho wabasebenzi.

Umsiki

Amathuluzi okugaya asetshenziswa kakhulu ahlanganisa abasiki bokugaya ekugcineni, abasiki bokugaya, ukwakha abasiki bokugaya kanye namathuluzi okugaya imbobo. Ukukhethwa nokusetshenziswa kwalawa mathuluzi kudinga ukunqunywa ngokuya ngemisebenzi ethile yemishini kanye nezinto zokusebenza ukuze kuqinisekiswe ikhwalithi yokucubungula nokusebenza kahle.

IV. Izinzuzo zempo imishini isikhungo

Ukunemba okuphezulu

Ingabona ukucubungula okunembayo okuphezulu futhi iqinisekise ukuthi usayizi nokunemba komumo we-workpiece ihlangabezana nezidingo eziqinile.

Ukuzinza okuphezulu

Isakhiwo siqinile futhi sizinzile, esingagcina ukusebenza kahle ngesikhathi sokusebenza isikhathi eside futhi sivumelane nezimo ezihlukahlukene zokucubungula eziyinkimbinkimbi.

Ukuvumelana nezimo okuqinile

Izinhlobonhlobo zezinhlobo ezahlukene zemisebenzi yokucubungula zingenziwa ukuze kuhlangatshezwane nezinguquko zezingxenye zokusebenza ezahlukene kanye nezidingo zokukhiqiza.

Ukusebenza okulula

Ngemva kokuqeqeshwa okuthile, opharetha angakwazi kahle izindlela zakhe zokusebenza futhi athuthukise ukusebenza kahle kokukhiqiza.

Ukuguquguquka okuhle

Sebenzisana nezinye izinto zokusebenza ukuze uthuthukise ukusebenza kahle kanye nokuxhumana kohlelo lokukhiqiza jikelele.

Kuqiza kahle

Nakuba ukutshalwa kwezimali kokuqala kungase kube phezulu, ukucutshungulwa kwayo okusebenzayo kanye nezindleko zokunakekelwa okuphansi kukwenza kungabizi kakhulu ekusetshenzisweni kwesikhathi eside.

V. Inkambu yohlelo lokusebenza yesikhungo semishini esime mpo

I-Aerospace

Isetshenziselwa ukukhiqiza izingxenye eziyinkimbinkimbi ze-aerospace, njengama-engine blades, izakhiwo zomzimba, njll.

Ukukhiqiza izimoto

Ukukhiqizwa kwezingxenye ezibalulekile ezifana nezinjini kanye nokudluliswa kwezimoto, kanye nokubunjwa komzimba, njll.

Ukukhiqiza ngomshini

Cubungula zonke izinhlobo zezingxenye zemishini, njengamagiya, amashafu, njll.

Imishini kagesi

Ukukhiqiza amagobolondo ezinto zikagesi, izingxenye zesakhiwo sangaphakathi, njll.

Imishini yezokwelapha

Khiqiza izingxenye zedivayisi yezokwelapha ezinembayo.

Ngamafuphi, njengenye yemishini ebalulekile embonini yesimanje, isikhungo somshini esime mpo sidlala indima engenakushintshwa emikhakheni ehlukahlukene ngemisebenzi yaso ehlukahlukene, ububanzi bokucubungula, imishini eyinkimbinkimbi kanye nezinzuzo eziningi. Ngokuqhubeka okuqhubekayo kwesayensi nobuchwepheshe kanye noshintsho oluqhubekayo lwesidingo sezimboni, isikhungo somshini esime mpo sizoqhubeka nokuthuthuka futhi sithuthuke, sifake amandla amasha kanye nomfutho ekuthuthukisweni kwemboni yokukhiqiza.

Ngokuzayo, singalindela isikhungo semishini esime mpo ukuthi senze impumelelo enkulu kwezobuhlakani kanye ne-automation. Ngokuhlanganiswa kobuchwepheshe bezinzwa obuthuthukisiwe, ubuhlakani bokwenziwa kanye nedatha enkulu, ukuqapha kwenqubo yokucubungula okuhlakaniphe kakhulu kanye nokwenza kahle kufinyelelwa. Ngaso leso sikhathi, ngokuthuthukiswa kwesayensi yezinto ezibonakalayo, ucwaningo nokuthuthukiswa kwamathuluzi amasha nezinto ezilungiswayo kuzothuthukisa ukusebenza kokucubungula nokusebenza kahle kwezikhungo zomshini eziqondile. Ukwengeza, ngaphansi komkhuba ojwayelekile wokukhiqiza uhlaza, izikhungo zokukhiqiza eziqondile zizophinde zithuthuke ngendlela yokonga ugesi kanye nokuvikelwa kwemvelo ukuze kuhlangatshezwane nezidingo zentuthuko esimeme.

Millingmachine@tajane.comLeli ikheli lama le-imeyili. Uma uyidinga, ungangithumelela i-imeyili. Ngilinde incwadi yakho eseShayina.