Amathuluzi Omshini we-CNC: Okhiye Nezinselele Zomshini Wokunemba Okuphezulu

Ithuluzi lomshini we-CNC, njengesifinyezo sethuluzi lomshini wokulawula idijithali, iyithuluzi lomshini elizenzakalelayo elifakwe uhlelo lokulawula uhlelo. Isistimu yayo yokulawula ingakwazi ukucubungula izinhlelo ngokunengqondo ngamakhodi okulawula noma eminye imiyalelo engokomfanekiso, futhi iwahlukanise, ukuze ithuluzi lomshini likwazi ukusebenza futhi licubungule izingxenye. Ukusebenza nokuqapha kweAmathuluzi omshini we-CNCzonke ziqediwe kule yunithi ye-CNC, engachazwa ngokuthi “ubuchopho” bethuluzi lomshini.

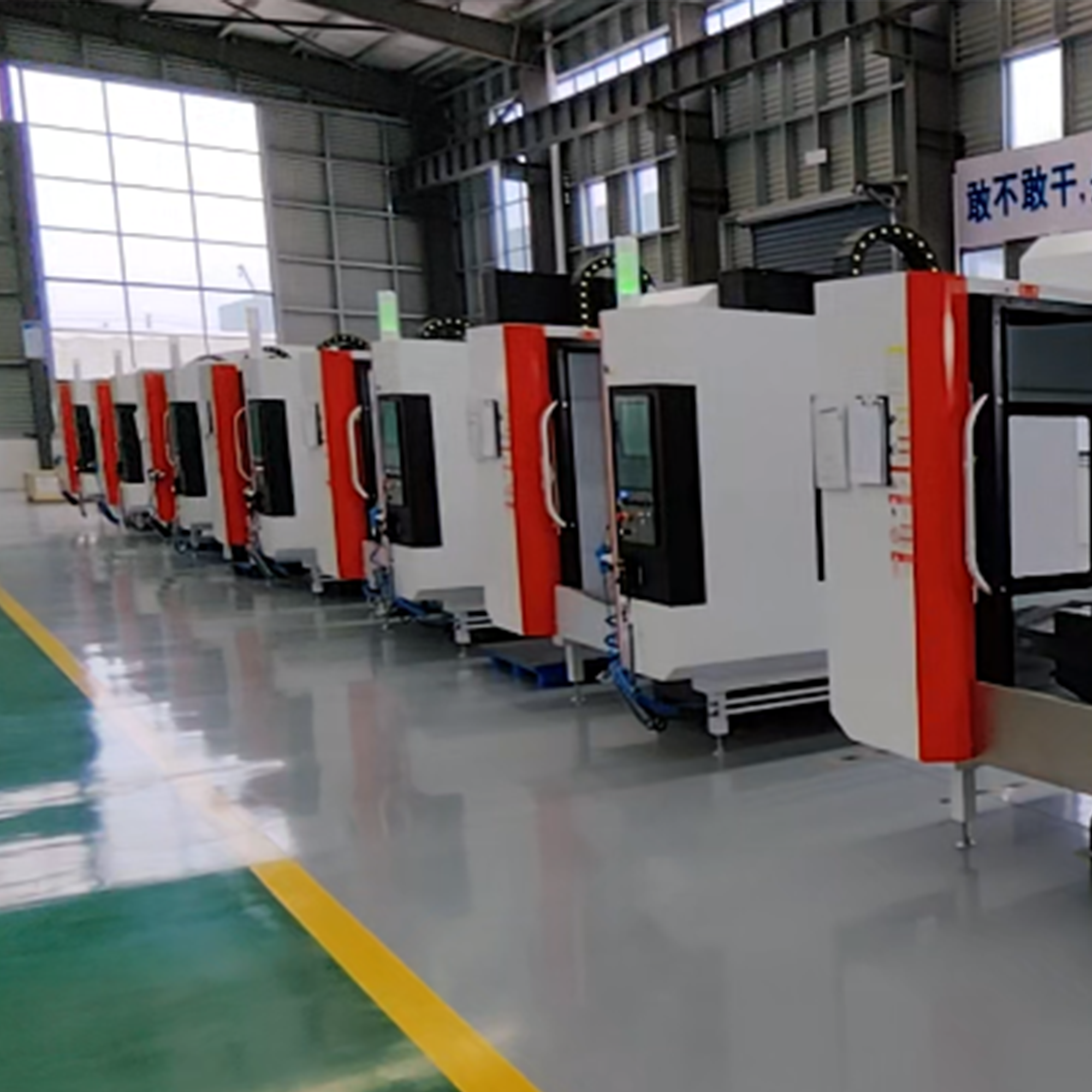

Amathuluzi omshini we-CNCzinezinzuzo eziningi. Ukunemba kokucubungula kwayo kuphezulu, okungaqinisekisa kancane kancane izinga lokucubungula; ingakwazi ukwenza ukuxhumana okuhlanganisa izinto eziningi, futhi ingacubungula izingxenye ezinobumo obuyinkimbinkimbi; lapho izingxenye zokucubungula zishintsha, ngokuvamile zidinga kuphela ukushintsha uhlelo lwe-CNC, olungasindisa kakhulu isikhathi sokulungiselela ukukhiqiza; ithuluzi lomshini ngokwalo linokunemba okuphezulu nokuqina okuphezulu, futhi lingakhetha inani elivumayo lokucubungula nokusebenza kahle kokukhiqiza. Iphakeme, imvamisa izikhathi ezi-3 kuya kwezi-5 kunamathuluzi omshini ajwayelekile; izinga eliphezulu le-automation, linganciphisa umfutho wabasebenzi. Kodwa-ke, iphinde ibeke phambili izidingo eziphezulu zekhwalithi yabaqhubi kanye nezidingo eziphezulu zobuchwepheshe zabasebenzi abalungisayo.

Amathuluzi omshini we-CNC ngokuvamile aqukethe izingxenye eziningi. Umshini oyinhloko ungumzimba oyinhloko weIthuluzi lomshini we-CNC, okuhlanganisa umzimba wethuluzi lomshini, ikholomu, ukuphotha, indlela yokuphakelayo nezinye izingxenye zemishini, ezisetshenziselwa ukuqedela imisebenzi ehlukahlukene yokusika nokucutshungulwa. Idivayisi yokulawula izinombolo iyingxenye yayo eyinhloko, okuhlanganisa i-hardware efana nebhodi lesifunda eliphrintiwe, isibonisi se-CRT, ibhokisi lokhiye, isifundi se-tape yephepha, njll., kanye nesofthiwe ehambisanayo, esetshenziselwa ukufaka izinhlelo zengxenye yedijithali, nokuqedela ukugcinwa kolwazi lokufakwayo, ukuguqulwa kwedatha, ukuhumusha kanye nokugcwaliseka kwemisebenzi yokulawula ehlukahlukene. Idivayisi yokushayela iyingxenye yokushayela yeIthuluzi lomshini we-CNCi-actuator, okuhlanganisa iyunithi ye-spindle drive, iyunithi yokuphakelayo, i-spindle motor kanye ne-feed motor, njll. Ngaphansi kokulawulwa kwedivayisi yokulawula izinombolo, i-spindle nesiphakeli kushayela ngesistimu ye-servo kagesi noma ye-electro-hydraulic. Lapho okuphakelayo okuningana kuxhunyaniswa, ukucutshungulwa kokuma, umugqa oqondile, ijika lendiza kanye nejika lesikhala kungaqedwa. Idivayisi eyinsiza iyingxenye edingekayo esekelayo yethuluzi lomshini we-CNC, njengokupholisa, ukukhishwa kwe-chip, ukugcoba, ukukhanyisa, ukuqapha, njll., okuhlanganisa amadivaysi e-hydraulic kanye ne-pneumatic, amadivaysi okukhipha ama-chip, amatafula okushintshanisa, ama-turntable e-CNC nokulawula izinombolo amakhanda ahlukanisayo, kanye namathuluzi nokuqapha nokubona. Ukuhlela nezinye izinto ezisetshenziswayo zingasetshenziselwa ukuhlela nokugcina izingxenye ngaphandle komshini.

Ekukhiqizeni, sivame ukuhlangana nezinkinga ngokunemba komshini okungavamile kwamathuluzi omshini we-CNC. Lolu hlobo lwenkinga lufihleke kakhulu futhi kunzima ukuluxilonga. Izizathu eziyinhloko zezinkinga ezinjalo yilezi ezilandelayo.

Okokuqala, iyunithi yokuphakelayo yethuluzi lomshini ingashintshwa noma ishintshwe. Lokhu kuzothinta ngokuqondile ukunemba komshini kwethuluzi lomshini, ngoba ukungajwayelekile kweyunithi yokuphakelayo kuzodala ukuchezuka ekuhambeni nasekumeni kwethuluzi lomshini.

Okwesibili, i-NULL OFFSET ye-eksisi ngayinye yethuluzi lomshini ayijwayelekile. I-Zero-point bias iyipharamitha ebalulekile ohlelweni lokuxhumanisa lwethuluzi lomshini. Ukungajwayelekile kwayo kuzokwenza ukuma kokuxhumanisa kwethuluzi lomshini kulahlekelwe ukunemba kwakho.

Ukwengeza, I-AXIAL REVERSE GAP (BACKLASH) ANOMALI FUTHI KUYIMBANGELA EVAMILE. I-reverse void isho igebe phakathi kwesikulufu namantongomane ekunyakazeni kwe-axial. Igebe lokuhlehla elingavamile lizothinta ukunemba nokuzinza kwethuluzi lomshini.

Ngaphezu kwalokho, isimo sokusebenza se-motor asivamile, okungukuthi, izingxenye zikagesi nezokulawula zihluleka. Lokhu kungase kuhlanganise ukwehluleka kwesifunda, ukwehluleka kwesilawuli noma ezinye izinkinga zikagesi, ezizothinta ngokuqondile ukusebenza okuvamile nokunemba kokucubungula kwethuluzi lomshini.

Ngaphezu kwalezi zizathu ezingenhla zemishini nekagesi, inhlangano yezinqubo zemishini, ukukhethwa kwamathuluzi nezici zobuntu kungase kuholele ekunembaneni komshini okungavamile. Ukuhlela okungenangqondo kungase kubangele amathuluzi omshini enze izenzo ezingalungile, futhi ukukhethwa kwamathuluzi okungafanele noma ukusetshenziswa okungafanele kuzophinde kuthinte ikhwalithi yokwenza imishini.

Ukuze ugweme noma uxazulule inkinga yokunemba kwemishini okungavamile kwamathuluzi omshini we-CNC, lezi zinyathelo ezilandelayo zingathathwa:

1. Hlola njalo futhi ulinganise iyunithi yokuphakelayo, ukuchema okuyiziro kanye neminye imingcele yethuluzi lomshini ukuze uqinisekise ukunemba kwalo.

2. Gcina futhi uhlole igebe le-axial reverse, futhi ulilungise noma ulilungise ngesikhathi.

3. Qinisa ukugcinwa nokuxazulula izinkinga zezingxenye zikagesi nokulawula.

4. Lungiselela ukuhlanganiswa kwezinqubo zokucubungula, khetha amathuluzi ngokunengqondo, futhi uqeqeshe abaqhubi ukuze bathuthukise amakhono abo nomuzwa wokuba nesibopho.

Ngamafuphi nje,Amathuluzi omshini we-CNCidlala indima ebalulekile ekukhiqizeni kwanamuhla, kodwa inkinga yokunemba kokucubungula okungavamile idinga ukunakwa ngokwanele. Ngokusetshenziswa okulungile, ukulungiswa kanye nokuxazulula inkinga kwamathuluzi omshini, ukunemba kokucubungula kungathuthukiswa ngempumelelo futhi nekhwalithi yomkhiqizo ingaqinisekiswa.

millingmachine@tajane.comLeli ikheli lama le-imeyili. Uma uyidinga, ungangithumelela i-imeyili. Ngilinde incwadi yakho eseShayina.