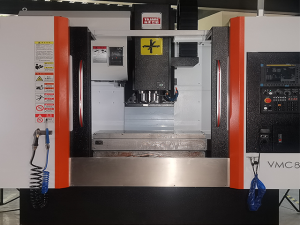

Njengesisetshenziswa esibalulekile nesibalulekile ekukhiqizweni kwezimboni zanamuhla,Umshini wokugaya we-CNCkunomthelela obalulekile ekusebenzeni kahle kanye nekhwalithi yokukhiqiza. Ukuze uqinisekise ukuthi umshini wokugaya we-CNC ungasebenza ngokuqhubekayo isikhathi eside, indlela efanele yokulungisa ibalulekile. Ake sixoxe ngamaphuzu okugcina weImishini yokugaya ye-CNCekujuleni ngeUmshini wokugaya we-CNCabakhiqizi.

I. Ukugcinwa kwesistimu yokulawula izinombolo

Uhlelo lwe-CNC luyingxenye eyinhloko ye-Umshini wokugaya we-CNC, nokugcinwa kwayo okuqinile kubaluleke kakhulu. Okokuqala, kufanele kwenziwe ngokuhambisana ngokuqinile nemithetho yokusebenza nokugcinwa kwesistimu yokulawula izinombolo ukuze kuqinisekiswe ukusebenza okuvamile kokushisa kokushisa kanye nesistimu yokuphefumula kwekhabhinethi kagesi. Ukukhipha ukushisa okungekuhle kanye nokungena komoya kungabangela isistimu ukuthi ishise kakhulu, ngaleyo ndlela kuthinte ukuzinza nokuphila kwesistimu.

Ngesikhathi esifanayo, kuyadingeka ukunciphisa ukusebenza kwamadivaysi okufaka nokukhipha okungadingekile futhi uwagcine futhi uwahlole njalo. Ibhulashi le-DC motor kanye ne-brushless DC motor izoguga kancane kancane ngesikhathi sokusetshenziswa. Lapho ukuguqulwa kokugqoka, kufanele kushintshwe ngesikhathi, ngaphandle kwalokho kuzothinta ukusebenza kwemoto futhi kubangele nokulimala kwemoto. NgobaIzinhlobo ze-CNC, Imishini yokugaya ye-CNC, izikhungo zomshini nezinye izinto zokusebenza, ukuhlolwa okuphelele kufanele kwenziwe kanye ngonyaka.

Kumabhodi esekethe esikhathi eside aphrintiwe wesekethe namabhodi esekethe ebhethri, kufanele ashintshwe njalo futhi afakwe ohlelweni lokulawula izinombolo isikhathi esithile ukuze kuvinjelwe umonakalo. Lokhu kungagcina ibhodi lesifunda lisesimweni esihle futhi liqinisekise ukuthi lingasebenza ngokujwayelekile lapho lidingeka.

II. Ukugcinwa kwezingxenye zemishini

Ukulungiswa kwebhande le-spindle drive

Kubaluleke kakhulu ukulungisa njalo ukuqina kwebhande le-spindle drive. Ibhande elixegayo lingase liholele ekusheleleni, lithinte isivinini sokujikeleza kanye nokudluliswa kwe-torque ye-spindle, futhi ngaleyo ndlela kuthinte ukunemba kwemishini nokusebenza kahle. Lesi simo singavinjelwa ngokulungisa ukuqina kwebhande ngendlela efanele.

Ukugcinwa kwe-spindle lubrication njalo ithangi lokushisa

Kudingekile ukuhlola ithangi lokushisa eliqhubekayo le-lubrication yokuphotha, ulungise ububanzi bokushisa, ugcwalise amafutha ngesikhathi, futhi uhlanze isihlungi. Ukugcoba okuhle nokulawula izinga lokushisa okungaguquki kusiza ukugcina isimo esihle sokusebenza se-spindle, ukunciphisa ukuguga nokuguquka kokushisa, futhi kuthuthukise ukunemba kokucubungula.

Ukunakwa kudivayisi yokubopha yokuphotha

Ngemva kokusetshenziswa isikhathi esideUmshini wokugaya we-CNC, idivayisi yokuhlanganisa ophothayo ingase ibe nezinkinga ezifana nezinotshi, ezizoba nomthelela ekubambeni kwethuluzi. Ngakho-ke, ukususwa kwe-hydraulic cylinder piston kufanele kulungiswe ngesikhathi ukuze kuqinisekiswe ukuthi ithuluzi lingaboshelwa ngokuqinile ukuze kugwenywe ukuxega noma ukuwa ngesikhathi sokucubungula.

Ukugcinwa kwamapheya entambo yesikulufu sebhola

Njalo hlola isimo sokubhangqa okufakwe isikulufu sebhola bese ulungisa ukuhlukana kwe-axial kokupheya okucushwe. Lokhu kungaqinisekisa ukunemba kokudluliswa kokuhlehla kanye nokuqina kwe-axial, futhi kuqinisekise ukunemba nokuzinza kwethuluzi lomshini phakathi nokunyakaza kokuphakelayo. Ngesikhathi esifanayo, kuyadingeka ukuhlola njalo ukuthi ukuxhumana phakathi kwesikulufa nombhede kukhululekile. Uma kukhona okuxekethile, kufanele kuqiniswe ngesikhathi. Uma idivayisi yokuvikela intambo yonakele, kufanele ishintshwe ngokushesha ukuze kuvinjwe uthuli noma ama-chips ukuthi angangeni epheya ewuchungechunge futhi abangele umonakalo.

III. Ukugcinwa kwezinhlelo ze-hydraulic kanye ne-pneumatic

Amasistimu we-Hydraulic kanye ne-pneumatic nawo adlala indima ebalulekile emishinini yokugaya ye-CNC. Ukugcinwa njalo kwezinhlelo ze-hydraulic kanye ne-pneumatic kubalulekile.

Okokuqala, isihlungi noma isihlungi kufanele sihlanzwe noma sishintshwe ukuze kuqinisekiswe ukuthi uwoyela negesi yezinhlelo ze-hydraulic kanye ne-pneumatic zihlanzekile. Amafutha ahlanzekile negesi kunganciphisa ukungcola nokungcola ohlelweni, futhi kunciphise ingozi yokuguga nokwehluleka kwezingxenye.

Okwesibili, ukuhlolwa kokuhlolwa kwamafutha okuvamile kanye nokushintshwa kwamafutha we-hydraulic ohlelweni lokucindezela kufanele kwenziwe. Uwoyela weHydraulic uzowohloka kancane kancane ngesikhathi sokusetshenziswa futhi ulahlekelwe ukusebenza kwawo okufanele. Ukushintshwa njalo kwamafutha we-hydraulic kungaqinisekisa ukusebenza okujwayelekile kohlelo lwe-hydraulic futhi kuthuthukise ukuthembeka kohlelo.

Ngaphezu kwalokho, isihlungi somoya kufanele sigcinwe njalo ukuze kuqinisekiswe ukuthi umoya ongena ohlelweni lwe-pneumatic uhlanzekile futhi womile. Ngesikhathi esifanayo, ukunemba komshini kufanele kuhlolwe futhi kulinganiswe njalo ukuze kuqinisekiswe ukuthi ithuluzi lomshini lisengakwazi ukugcina umthamo wokucubungula wokunemba okuphezulu ngemva kokusetshenziswa isikhathi eside.

IV. Amanye amaphuzu okunakekela

Ngaphezu kwalezi zici ezingenhla zesondlo, kunezinye izinto okufanele zibhekwe.

Okokuqala, indawo yokusebenza yomshini wokugaya i-CNC kufanele igcinwe ihlanzekile futhi icocekile. Gwema uthuli, udoti, njll. ukungena ethuluzini lomshini, elinomthelela ekunembeni nasekusebenzeni kwethuluzi lomshini.

Okwesibili, u-opharetha kufanele asebenze ngokuhambisana ngokuqinile nezinqubo zokusebenza ukuze agweme ukulimala kwethuluzi lomshini okubangelwa ukungasebenzisi kahle. Ngesikhathi esifanayo, kuyadingeka ukuqinisa ukuqeqeshwa kwabaqhubi kanye nokuthuthukisa amakhono abo okusebenza nokuqwashisa kokugcinwa.

Ngaphezu kwalokho, kuyadingeka ukusungula amarekhodi okugcinwa okuphelele namafayela. Rekhoda okuqukethwe, isikhathi, abasebenzi kanye nolunye ulwazi lwesondlo ngasinye ngokuningiliziwe ukuze kulandeleke futhi kuhlaziywe. Ngokuhlaziywa kwamarekhodi okugcinwa, izinkinga kanye nezingozi ezifihliwe zamathuluzi omshini zingatholakala ngesikhathi futhi izinyathelo ezihambisanayo zingathathwa ukuzixazulula.

Ngamafuphi nje, ukugcinwa kwemishini yokugaya ye-CNC kuwumsebenzi ohlelekile futhi ocophelelayo, odinga imizamo ehlanganyelwe yabaqhubi kanye nabasebenzi bokunakekela. Ngokusebenzisa indlela efanele yokulungisa, impilo yesevisi yomshini wokugaya we-CNC inganwetshwa, ukunemba kokucubungula kwayo nokusebenza kahle kungathuthukiswa, futhi ukukhiqizwa nokuthuthukiswa kwamabhizinisi kunganikezwa ngokusekelwa okuqinile. Enqubweni yokulungiswa, ukusebenza kufanele kwenziwe ngokuhambisana ngokuqinile nezidingo kanye nemininingwane yomkhiqizi ukuze kuqinisekiswe ukusebenza kahle nokuphepha komsebenzi wokulungisa. Ngesikhathi esifanayo, kufanele sifunde njalo futhi sisebenzise ubuchwepheshe obusha bokulungisa nezindlela, sithuthukise njalo izinga lokulungisa, futhi siphelezele ukusebenza kahle kwemishini yokugaya ye-CNC.

Millingmachine@tajane.com This is my email address. If you need it, you can email me. I’m waiting for your letter in China.