Emkhiqizweni wezimboni zanamuhla,Umshini wokugaya we-CNCunesikhundla esibalulekile. Ukuze kuqinisekiswe ukusebenza kwayo okuzinzile nokusebenza kahle kwesikhathi eside, ukunakekelwa okufanele kubaluleke kakhulu. Ake sixoxe ngendlela yokugcinwa komshini wokugaya we-CNC ngokujulile neUmshini wokugaya we-CNCumkhiqizi.

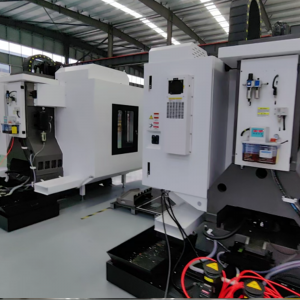

I. Ukugcinwa kwesistimu yokulawula izinombolo

Uhlelo lwe-CNC luyingxenye eyinhloko ye-Umshini wokugaya we-CNC, nokugcinwa ngokucophelela kuyisihluthulelo sokuqinisekisa ukusebenza okuvamile kwethuluzi lomshini.

Sebenza ngokuhambisana ngokuqinile nemininingwane yokusebenza yesistimu yokulawula izinombolo ukuze uqinisekise ukuqalisa, ukusebenza kanye nezinqubo ezifanele zokuvala. Ukujwayelana nokulandela izidingo zesistimu yokukhipha ukushisa kanye ne-ventilation yekhabhinethi kagesi, qinisekisa indawo enhle yokukhipha ukushisa ekhabetheni likagesi, futhi uvimbele ukwehluleka kwesistimu okubangelwa ukushisa ngokweqile.

Okokufaka nokukhiphayo, kufanele kugcinwe njalo. Hlola ukuthi ulayini wokuxhuma ukhululekile futhi isixhumi esibonakalayo sijwayelekile ukuze uqinisekise ukunemba nokuzinza kokudluliswa kwedatha.

Ukuguga nokudabuka kwebhulashi lemoto ye-DC kudinga ukunakwa kakhulu. Ukushintsha kokugqoka kwebhulashi kuzothinta ukusebenza kwenjini futhi kungase kubangele nokulimala kwemoto. Ngakho-ke, ibhulashi likagesi kufanele lihlolwe njalo futhi lishintshwe ngesikhathi. Okwezintambo ze-CNC,Imishini yokugaya ye-CNC, izikhungo zemishini kanye nezinye izinto zokusebenza, kunconywa ukwenza ukuhlolwa okuphelele kanye ngonyaka.

Kumabhodi esekethe esikhathi eside aphrintiwe wesekethe kanye namabhodi esekethe ebhethri, kufanele ashintshwe njalo. Yifake ohlelweni lwe-CNC isikhathi esithile ukuze uvimbele umonakalo odalwe ukungenzi lutho kwesikhathi eside.

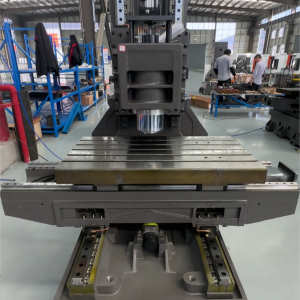

II. Ukugcinwa kwezingxenye zemishini

Ukugcinwa kwebhande le-spindle drive akunakuzitshwa. Lungisa njalo ukuqina kwebhande ukuvimbela ukushelela kwebhande. I-Skidding ngeke nje ithinte ukunemba kokucubungula, kodwa futhi kuholele ekuhlulekeni kwemishini.

Hlola ngokucophelela ithangi lokushisa elingashintshi le-spindle. Lungisa izinga lokushisa, qinisekisa ukuthi izinga lokushisa likawoyela lingaphakathi kwebanga elifanele, gcwalisa uwoyela ngesikhathi, futhi ugeze isihlungi njalo ukuze uqinisekise ukuhlanzeka nomphumela wokugcoba uwoyela.

Ngemuva kokusetshenziswa isikhathi esideUmshini wokugaya we-CNC, kungase kube nezinkinga ngomshini wokugoqa ophothayo. Isibonelo, kungase kube nezikhala, ezizothinta i-clamping yamathuluzi. Ukususwa kwe-hydraulic cylinder piston kufanele kulungiswe ngesikhathi ukuze kuqinisekiswe ukuthi i-clamping yamathuluzi iqinile futhi ithembekile.

Hlola njalo isimo sokubhanqwa kwentambo yesikulufu sebhola. Lungisa ukuhlukana kwe-axial kokupheya okunentambo ukuze uqinisekise ukunemba kokudlulisela okuhlanekezela kanye nokuqina kwe-axial. Ngesikhathi esifanayo, hlola ukuthi ukuxhumana phakathi kwesikulufa nombhede kukhululekile, futhi ukuqinise ngesikhathi uma kutholakala ukuthi kukhululekile. Uma idivayisi yokuqapha intambo yonakele, kufanele ishintshwe ngokushesha ukuvimbela uthuli noma ama-chips ukuthi angangeni, okubangele ukulimala kwesikulufa.

III. Ukugcinwa kwezinhlelo ze-hydraulic kanye ne-pneumatic

Gcina njalo amasistimu we-hydraulic kanye ne-pneumatic. Geza noma shintsha isihlungi noma isihlungi ukuze uqinisekise ukuhlanzwa kwemithombo kawoyela negesi kumasistimu asebenza ngamanzi kanye nawomoya.

Hlola njalo izinga likawoyela we-hydraulic kanye nesimo sokusebenza sohlelo lokucindezela. Shintsha uwoyela we-hydraulic ngesikhathi ngokwezidingo ukuze uqinisekise ukusebenza okuvamile kwesistimu ye-hydraulic.

Gcina isihlungi somoya njalo ukuze uvimbele ukungcola okusemoyeni ukuthi kungangeni ohlelweni lwe-pneumatic. Ngesikhathi esifanayo, ukunemba komshini kufanele kuhlolwe njalo, futhi kulungiswe futhi kulungiswe ngesikhathi ukuze kuqinisekiswe ukuthi ukunemba kokucubungula kuhlala kugcinwa ezingeni eliphezulu.

IV. Isondlo kwezinye izici

Ukubukeka kweUmshini wokugaya we-CNCkufanele futhi ihlanzwe njalo. Susa uthuli, uwoyela nemfucumfucu endaweni bese ugcine amathuluzi omshini ecocekile. Lokhu akugcini nje ngokuhambisana nobuhle, kodwa futhi kuvimbela uthuli nokunye ukungcola ekungeneni kwethuluzi lomshini, okuthinta ukusebenza kwemishini.

Hlola njalo ukuthi idivayisi yokuvikela yethuluzi lomshini ayilungile yini. Idivayisi yokuvikela ingavikela ngempumelelo u-opharetha kanye nethuluzi lomshini ekulimaleni ngengozi nasekulimaleni, futhi kufanele iqinisekise ukusebenza kwayo okuvamile.

Izinsimbi zomhlahlandlela, izikulufu kanye nezinye izingxenye ezibalulekile zeUmshini wokugaya we-CNCkufanele igcotshwe njalo. Khetha i-lubricant efanele futhi uyifake noma uyengeze ngokuvumelana nesikhathi esinqunyiwe kanye nendlela yokunciphisa ukuguga nokwandisa impilo yesevisi yengxenye.

Naka indawo ezungezile ithuluzi lomshini. Gwema ukusebenzisa amathuluzi omshini endaweni enomswakama, izinga lokushisa eliphezulu, uthuli nezinye izindawo ezinokhahlo, bese uzama ukudala indawo yokusebenza enhle yamathuluzi omshini.

Ukuqeqeshwa kwabaqhubi nakho kubalulekile. Qinisekisa ukuthi u-opharetha ujwayelene nokusebenza, indlela yokusebenza kanye nezidingo zokunakekelwa kwethuluzi lomshini, futhi usebenza ngokuhambisana ngokuqinile nezinqubo zokusebenza. Kuphela ngokuhlanganisa ukusebenza okulungile nokugcinwa ngokucophelela kungenza ukusebenza kahle kweImishini yokugaya ye-CNCzilethwe ngokugcwele.

Sungula uhlelo oluphelele lokugcinwa kwerekhodi. Rekhoda okuqukethwe, isikhathi kanye nezisebenzi zokunakekela kanye nolunye ulwazi lwesondlo ngasinye ngokuningiliziwe ukuze kulandeleke futhi kuhlaziywe. Ngokuhlaziywa kwamarekhodi okugcinwa, izinkinga nezingozi ezifihliwe zamathuluzi omshini zingatholakala ngesikhathi, futhi izinyathelo ezihlosiwe zingathathwa ukuzixazulula.

Kwezinye izingxenye zokugqoka nezinto ezisetshenziswayo, izingxenye eziyisipele ezanele kufanele zilungiswe kusenesikhathi. Ngale ndlela, ingenziwa ngesikhathi lapho idinga ukushintshwa, ukuze ugweme ukuphumula kwethuluzi lomshini ngenxa yokuntuleka kwezingxenye ezisele futhi kuthinte inqubekelaphambili yokukhiqiza.

Njalo umeme abasebenzi abalungisayo ukuze bahlole futhi banakekele amathuluzi omshini. Banolwazi oluningi lochwepheshe namakhono okuthola ezinye izinkinga ezingase zibe khona futhi baphakamise izixazululo ezifanele.

Qinisa ukuhlolwa kwansuku zonke kwamathuluzi omshini. Emsebenzini wansuku zonke, opharetha kufanele ngaso sonke isikhathi banake isimo sokusebenza kwethuluzi lomshini, futhi bame futhi bahlole ngesikhathi uma bethola izimo ezingavamile, ukuze bagweme izinkinga ezincane eziphenduka ukwehluleka okukhulu.

Gcina ukuxhumana okuseduze noUmshini wokugaya we-CNCabakhiqizi. Hlala wazi ngobuchwepheshe bakamuva nezindlela zokunakekela zamathuluzi omshini, futhi uthole ukwesekwa kobuchwepheshe kanye nesevisi yangemva kokuthengisa kubakhiqizi. Lapho uhlangabezana nezinkinga ezinzima, ungathintana nomkhiqizi ngesikhathi ukuze uthole usizo lochwepheshe.

Ngamafuphi, ukugcinwa kweUmshini wokugaya we-CNCkuwumsebenzi ohlelekile futhi ocophelelayo, odinga ukuqala ezicini eziningi. Kuphela ngokusebenzisa zonke izindlela zokunakekela singakwazi ukuqinisekisa ukuthiUmshini wokugaya we-CNCnjalo igcina ukusebenza okuhle nesimo sokusebenza, idala inani elikhulu lebhizinisi. Ngesikhathi esifanayo, amabhizinisi kufanele anamathisele ukubaluleka okukhulu ekunakekeleniImishini yokugaya ye-CNC, yenza izinhlelo zokulungisa ezingokwesayensi nezinengqondo, futhi ulandele ngokuqinile uhlelo. Abaqhubi kanye nabasebenzi abalungisayo kufanele bahlale bethuthukisa izinga labo kanye nezinga lamakhono, benze ngobuqotho izibopho zokunakekela, futhi banikeze isiqinisekiso esiqinile sokusebenza kwesikhathi eside nokuzinzile kweImishini yokugaya ye-CNC. Esikhathini esizayo ukukhiqizwa kwezimboni,Imishini yokugaya ye-CNCizoqhubeka nokudlala indima ebalulekile, futhi ukulungiswa okufanele kuyoba ukhiye wokuqinisekisa ukusebenza kwayo ngempumelelo. Asisebenzisane ukwenza umsebenzi omuhle ekunakekeleniImishini yokugaya ye-CNCkanye nokukhuthaza intuthuko eqhubekayo kanye nenqubekelaphambili yokukhiqizwa kwezimboni.

Enqubweni yokulungiswa kwangempela, sidinga futhi ukunaka amaphuzu alandelayo:

Ukuphepha kuqala. Lapho senza noma yimuphi umsebenzi wokulungisa, kufanele silandele ngokuqinile izinqubo zokusebenza zokuphepha ukuze siqinisekise ukuphepha komuntu siqu kwabaqhubi.

Qaphela futhi ubekezele. Umsebenzi wokunakekela udinga ukucophelela, kungabi nobudlabha. Qaphela futhi ube nomthwalo wemfanelo wokuhlolwa nokunakekelwa kwazo zonke izingxenye ukuze uqinisekise ukuthi ayikho ingozi efihliwe esindayo.

Qhubeka ufunda. Ngokuthuthuka okuqhubekayo kanye nokuvuselelwa kobuchwepheshe, izindlela zokugcinwa kweImishini yokugaya ye-CNCnazo zishintsha njalo. Izisebenzi zesondlo kufanele ziqhubeke nokufunda futhi zihlale zithuthukisa ulwazi namakhono azo ukuze zihlangabezane nezidingo ezintsha zesondlo.

Ukusebenza ngokubambisana. Ukunakekela ngokuvamile kudinga ukubamba iqhaza ngokubambisana kanye nokusebenzisana kweminyango eminingi nabasebenzi. Kuyadingeka ukuqinisa ukuxhumana nokuxhumana, ukwakha amandla okusebenza ahlangene, nokuqinisekisa ukuqhubeka kahle komsebenzi wokulungisa.

Ukulawula izindleko. Lapho senza umsebenzi wokulungisa, kufanele sihlele izinsiza ngokunengqondo futhi silawule izindleko. Kudingekile ukuthi ungagcini nje ngokuqinisekisa umphumela wesondlo, kodwa futhi ugweme imfucuza engadingekile.

Ukuqwashisa ngemvelo. Enqubweni yokunakekelwa, kufanele sinake ukuvikelwa kwemvelo, silahle kahle amafutha angcolile, izingxenye, njll, futhi sinciphise ukungcoliswa kwemvelo.

Ngokusebenzisa lezi zinyathelo zokunakekela eziphelele ezingenhla kanye nezinyathelo zokuphepha, singaqinisekisa kangcono ukusebenza okuvamile nempilo yesevisi yeImishini yokugaya ye-CNC, futhi adale izinzuzo ezengeziwe zezomnotho nezenhlalo zamabhizinisi. Asisebenzisane ukuze sikhuthaze ukuthuthukiswa okuqhubekayo nokuthuthukiswa kokugcinwa kokunakekelwa kweImishini yokugaya ye-CNCkanye neqhaza ekuthuthukisweni kwezimboni.

Ngaphezu kwalokho, singasebenzisa izindlela ezintsha zokulungisa nobuchwepheshe obulandelayo:

Uhlelo lokulungisa oluhlakaniphile. Ukusebenzisa izinzwa eziphambili kanye nobuchwepheshe bokuqapha, isimo sokusebenza kanye nemingcele yeUmshini wokugaya we-CNCzigadwa ngesikhathi sangempela, futhi izinkinga zitholakala ngesikhathi kanye nezixwayiso kusenesikhathi zikhishwa. Ngesikhathi esifanayo, ngokuhlaziywa kwedatha kanye nama-algorithms ahlakaniphile, inikeza isisekelo sokuthatha izinqumo zesayensi ngomsebenzi wokulungisa.

Isevisi yokulungisa kude. Ngosizo lwe-inthanethi nobuchwepheshe bokuxhumana obukude, ukuxhumana okukude phakathiUmshini wokugaya we-CNCabakhiqizi kanye nabasebenzisi bayaqaphela. Abakhiqizi bangakwazi ukuqapha bekude futhi bahlole amathuluzi omshini, futhi banikeze isiqondiso sokugcinwa kwesilawuli kude nosekelo lobuchwepheshe.

Ukugcinwa kokubikezela. Ngokuhlaziya idatha yomlando kanye nesimo sokusebenza kwe-ithuluzi lomshini, zibikezele amaphutha nezinkinga ezingaba khona, futhi zithathe izinyathelo zokuvimbela nokugcina kusenesikhathi ukugwema ukwenzeka kokwehluleka.

Ubuchwepheshe bokulungisa okuluhlaza. Sebenzisa izinto zokuthambisa ezingayingeni imvelo, izinto zokuhlanza nezinye izinto zokulungisa ukuze unciphise ukungcoliswa kwemvelo. Ngesikhathi esifanayo, hlola izindlela zokulondoloza ukonga amandla ukuze unciphise ukusetshenziswa kwamandla kwamathuluzi omshini.

Ukusetshenziswa kobuchwepheshe bokuphrinta be-3D ekukhiqizeni izingxenye ezisele. Kwezinye izingxenye eziyisipele okunzima ukuzithenga, ubuchwepheshe bokuphrinta be-3D bungasetshenziselwa ukwakha, ukufinyeza umjikelezo wokunikeza izingxenye eziyisipele, nokuthuthukisa ukusebenza kahle kokulungisa.

Ukuhlaziywa kwedatha enkulu nezinqumo zokulondoloza. Qoqa futhi uhlele inombolo enkulu yedatha yokugcinwa kwamathuluzi omshini, hlola inani elingaba khona ledatha ngobuchwepheshe obukhulu bokuhlaziya idatha, futhi unikeze isisekelo sokwenza izinhlelo namasu okulondoloza esayensi nenengqondo.

Lezi zindlela ezintsha zokulungisa kanye nobuchwepheshe zizoletha amathuba amasha nezinselele ekugcinweni kwempahlaImishini yokugaya ye-CNC. Amabhizinisi kanye neminyango efanele kufanele ihlole futhi isebenzise lobu buchwepheshe obusha ukuze iqhubeke ithuthukisa izinga lokulungisa kanye nekhwalithiImishini yokugaya ye-CNC.

Ngamafuphi, ukugcinwa kweImishini yokugaya ye-CNCkuwumsebenzi wesikhathi eside nonzima, odinga imizamo yethu eqhubekayo nokusungula izinto ezintsha. Ngezinyathelo zesayensi nezinengqondo zokulungisa, izindlela zobuchwepheshe ezithuthukile kanye nezidingo eziqinile zokuphatha, sizokwazi ukuqinisekisa ukusebenza okuzinzile nokusebenza kahle kwesikhathi esideImishini yokugaya ye-CNCkanye nokuba negalelo elikhulu ekuthuthukiseni amabhizinisi kanye nenqubekelaphambili yomphakathi. Asisebenzisane ukuze sakhe ikusasa lezimboni elingcono!

Millingmachine@tajane.comLeli ikheli lama le-imeyili. Uma uyidinga, ungangithumelela i-imeyili. Ngilinde incwadi yakho eseShayina.