CNC Machining Center: umnyombo wobuchwepheshe bokukhiqiza obuphambili

I. Isingeniso

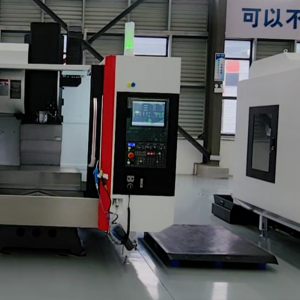

Embonini yesimanje yokukhiqiza,CNC Machining Center, njengethuluzi elibalulekile lomshini we-CNC, lidlala indima ebalulekile. Ihlanganisa ubuchwepheshe obuthuthukisiwe kanye nemisebenzi ukuze kuzuzwe ukusebenza kahle nokunembile kokucubungula futhi inikeze izingxenye nemikhiqizo yekhwalithi ephezulu yezimboni ezihlukahlukene. Lesi sihloko sizoxoxa ngokujulile ngezici, izimiso zokucubungula, izinzuzo kanye nokushiyeka kweCNC Machining izikhungo, futhi ihlaziye ukusetshenziswa kwazo kanye nentuthuko yesikhathi esizayo embonini yokukhiqiza.

II. Izici ze-CNC Machining Center

CNC machining centre ithuthukiswe ngesisekeloImishini yokugaya ye-CNC, kodwa inezici eziyingqayizivele eziyihlukanisa nemishini yokugaya ye-CNC. Esinye sezici ezibaluleke kakhulu umtapo wayo wommese kanye nekhono lokushintsha imimese ngokuzenzakalelayo. Ngalesi sisetshenziswa sokushintsha ithuluzi elizenzakalelayo, isikhungo somshini singashintsha amathuluzi ahlukahlukene ahlukene ekubambeni okukodwa, ukuze kuqedelwe imisebenzi ehlukahlukene yokumaka. Lesi sici sithuthukisa kakhulu ukusebenza kahle kokucubungula nokuvumelana nezimo, sinciphisa inani lokuqiniswa kwama-workpieces, futhi sinciphisa amathuba okuba namaphutha omshini.

Ngaphezu kwalokho, izikhungo zemishini ye-CNC zivame ukuhlonyiswa ngezinhlelo zokulawula ukunemba okuphezulu kanye nobuchwepheshe bokushayela obuphambili, obungaqinisekisa ukunemba nokuzinza kwemishini. Ingakwazi ukucubungula ama-workpieces anobumo nobukhulu obuhlukahlukene, kungakhathaliseki ukuthi i-geometry elula noma indawo eyinkimbinkimbi, okungabhekwana nayo kalula. Ngesikhathi esifanayo, isikhungo somshini sinamandla okusika aqinile kanye nokusebenza kwejubane eliphezulu, okungahlangabezana nezidingo zezimboni ezahlukene zokucubungula ukusebenza kahle kanye nekhwalithi.

III. Izimiso zokunqunywa kwemizila yokucubungula

Enqubweni yesikhungo semishini ye-CNC, kubaluleke kakhulu ukunquma ngokunengqondo umzila wokucubungula. Okulandelayo yizimiso ezivame ukulandelwa:

1. Ukuqinisekisa ukunemba kanye nobulukhuni obuphezulu bendawo yokusebenza: Idizayini yomzila womshini kufanele kuqala icabangele indlela yokuqinisekisa ukunemba kanye nezidingo zokuqina kwendawo yesiqephu sokusebenza esicutshunguliwe. Lokhu kudinga ukucatshangelwa okuphelele kwezinto ezinjengokukhethwa kwamathuluzi, ukulungiselelwa kwepharamitha yokusika kanye nokulandelana komshini. Ngokuhlela okunengqondo, amaphutha okucubungula angancishiswa kanye nezinga lezinto zokusebenza zingathuthukiswa.

2. Nciphisa umzila wokucubungula: Ukuze uthuthukise ukusebenza kahle kokucubungula, umzila wokucubungula kufanele ufinyezwe ngangokunokwenzeka futhi isikhathi sokuhamba esingenalutho kufanele sincishiswe. Lokhu kungafezwa ngokulungiselela indlela yamathuluzi nokuhlela ngokunengqondo inqubo yokucubungula. Ngesikhathi esifanayo, gwema ukucubungula okuphindaphindiwe okungadingekile nemizila ezungezayo ukuze wonge isikhathi sokucubungula namandla.

3. Isibalo sezinombolo esenziwe lula: Ukunqunywa komzila wokucubungula kufanele kwenze umthwalo wokubala izinombolo ube lula ngangokunokwenzeka ekuhleleni nasekusebenzeni. Lokhu kungafezwa ngokukhetha isistimu yokudidiyela efanele kanye nokusebenzisa umkhondo wethuluzi ojwayelekile. Ukwenza lula uhlelo lokucubungula akukwazi nje ukuthuthukisa ukusebenza kahle kwezinhlelo, kodwa futhi kunciphisa amathuba okuba namaphutha ohlelo.

4. Ukusetshenziswa kwama-subroutines: Kwezinye izinhlelo eziphinde zasetshenziswa, ama-subroutines kufanele asetshenziselwe ukuhlela. Lokhu kunganciphisa ubude bohlelo futhi kuthuthukise ukusebenza kahle nokufundeka kwezinhlelo. Ngesikhathi esifanayo, i-subroutine ingabuye ishintshwe kalula futhi igcinwe ukuze kuthuthukiswe ukuguquguquka nokusebenziseka kabusha kohlelo.

IV. Izinzuzo zeCNC Machining Center

CNC Machining Centerinezinzuzo eziningi ezibalulekile, eziyenza isetshenziswe kabanzi embonini yesimanje yokukhiqiza:

1. Yehlisa inani lamathuluzi: Ngenxa yokuthi isikhungo somshini singakwazi ukufeza imisebenzi ehlukahlukene yemishini ngokushintsha ithuluzi elizenzakalelayo, asidingi inani elikhulu lamathuluzi ayinkimbinkimbi lapho sicubungula izingxenye ezinobumo obuyinkimbinkimbi. Kuphela ngokushintsha uhlelo lokucubungula izingxenye, ukucutshungulwa kwezingxenye zomumo nobukhulu obuhlukene kungenziwa, okunciphisa kakhulu inani nezindleko zamathuluzi. Lokhu kuzuzisa kakhulu ekuthuthukisweni nasekuguqulweni kwemikhiqizo emisha, futhi kungasabela ngokushesha esidingweni semakethe.

2. Izinga lokucubungula elizinzile: Isikhungo somshini sifakwe uhlelo lokulawula ukunemba okuphezulu kanye nobuchwepheshe obuphambili bokushayela, obungaqinisekisa izinga elizinzile lokucubungula. Inokunemba okuphezulu kokucubungula nokuphindaphinda, okungahlangabezana nezidingo zezimboni ezinemba okuphezulu njengezindiza. Ukwengeza, inqubo yokucubungula yesikhungo sokucubungula izinzile futhi ayithinteki kangako izici zomuntu, okulungele ukuqinisekisa ukuhambisana kwekhwalithi yomkhiqizo.

3. Ukusebenza kahle kokukhiqiza okuphezulu: Endabeni yokukhiqiza okuhlukahlukene kanye nevolumu encane, iCNC Machining Centeringanikeza ukudlala okugcwele ezinzuzweni zayo eziphumelelayo. Ngokunciphisa isikhathi sokulungiselela ukukhiqiza, ukulungiswa kwethuluzi lomshini kanye nokuhlolwa kwenqubo, nokusebenzisa inani elingcono kakhulu lokusika ukunciphisa isikhathi sokusika, isikhungo somshini singathuthukisa kakhulu ukusebenza kahle kokukhiqiza. Ngesikhathi esifanayo, ikhono layo lokucubungula elivumelana nezimo lingahlangabezana nezidingo zomuntu siqu zamakhasimende ahlukene futhi lithuthukise ukuncintisana kwemakethe kwamabhizinisi.

4. Indawo eyinkimbinkimbi engacutshungulwa:CNC Machining izikhungoingacubungula izindawo eziyinkimbinkimbi okunzima ukuzicubungula ngezindlela ezijwayelekile, njengezindawo ezigobile, izindawo ezimise okukhethekile, njll. Ngisho nasezinxenyeni ezithile ezingabonakali zokucubungula, zingacutshungulwa ngokunembile ngobuchwepheshe bokulawula izinombolo. Lokhu kunikeza indawo ebanzi yokuklama kanye namathuba okukhiqiza embonini yokukhiqiza, futhi kusiza ukukhuthaza ukusungulwa nokuthuthukiswa komkhiqizo.

V. Okubi kwe-CNC Machining Center

Yize isikhungo semishini ye-CNC sinezinzuzo eziningi, kukhona nokushiyeka okudingeka kubhekwe:

1. Izindleko zemishini yamathuluzi omshini ziyabiza: inani lempahla yeCNC Machining izikhungoliphezulu uma kuqhathaniswa, okungase kube umthwalo omkhulu wokutshalwa kwezimali kwamanye amabhizinisi amancane naphakathi nendawo. Ukwengeza, izindleko zayo zokuyigcina kanye nokugcinwa kwayo ziphakeme kakhulu, okudinga ukuthi ochwepheshe abaqeqeshiwe basebenze futhi banakekele.

2. Idinga abasebenzi bezokulungisa ukuthi babe nezinga eliphezulu: Njengoba isikhungo somshini we-CNC siwubuchwepheshe obuphezulu.Ithuluzi lomshini we-CNC, ukulungiswa nokugcinwa kwayo kudinga ulwazi lobuchwepheshe namakhono. Izisebenzi zokunakekela izingane zidinga ukujwayelana nesakhiwo, isimiso kanye nesistimu yokulawula yethuluzi lomshini, futhi bakwazi ukwahlulela ngokushesha nangokunembile futhi baxazulule amaphutha. Emabhizinisini, kuyadingeka ukuqeqesha noma ukuqasha abasebenzi bezokulungisa, okwandisa izindleko zabasebenzi zebhizinisi.

VI. Ukusetshenziswa kwe-CNC Machining Center

Isikhungo semishini ye-CNC sisetshenziswa kabanzi ezimbonini ezahlukahlukene. Okulandelayo ezinye izinkambu ezijwayelekile zohlelo lokusebenza:

1. Inkambu ye-Aerospace: Emkhathini we-aerospace, ukunemba kanye nekhwalithi yezingxenye ziphezulu kakhulu. ICNC Machining Centeringacubungula izingxenye ezihlukahlukene zomumo oyinkimbinkimbi, njengama-blade enjini yendiza, izingxenye zesakhiwo semikhumbi-mkhathi, njll., ukuze kuhlangatshezwane nezidingo eziphezulu emkhakheni we-aerospace.

2. Imboni yokukhiqiza izimoto: Imboni yokukhiqiza izimoto ingenye yezinkambu ezibalulekile zokusetshenziswa kwezikhungo zemishini ye-CNC. Isikhungo somshini we-CNC singasetshenziselwa ukucubungula izingxenye ezibalulekile ezifana nebhulokhi yesilinda senjini yemoto, i-cylinder head kanye ne-crankshaft, kanye nezingxenye ezinkulu ezifana nomzimba wemoto kanye no-chassis. Ikhono layo elisebenza kahle nelinembile lokucubungula lingathuthukisa ikhwalithi nokusebenza kahle kokukhiqizwa kwezimoto.

3. Imboni yokukhiqiza isikhunta: Ukukhiqiza isikhunta kungenye insimu yesicelo esibalulekileCNC Machining Center. Ukunemba kanye nekhwalithi yesikhunta kuthinta ngqo ikhwalithi nokusebenza kahle kokukhiqiza komkhiqizo. Isikhungo somshini we-CNC singacubungula izimo ezihlukahlukene eziyinkimbinkimbi zokubumba, ezifana nezibunjwa zomjovo, isikhunta se-die-casting, ukubumba isitembu, njll., ukuhlinzeka ngosizo oluthembekile lwezobuchwepheshe embonini yokukhiqiza isikhunta.

4. Imboni yezogesi: Embonini yezogesi,CNC Machining izikhungoingasetshenziswa ukucubungula izingxenye ezihlukahlukene ze-elekthronikhi, njengamabhodi wesekethe aphrintiwe, amagobolondo omakhalekhukhwini, amagobolondo ekhompiyutha, njll. Ukunemba kwayo okuphezulu kanye nekhono lokucubungula ngesivinini esiphezulu kungahlangabezana nezidingo zemboni ye-electronics ngokunemba kanye nekhwalithi yezingxenye.

5. Imboni yemishini yezokwelapha: Imboni yemishini yezokwelapha nayo inezidingo eziphakeme kakhulu zokunemba kanye nekhwalithi yezingxenye. Isikhungo somshini we-CNC singacubungula izingxenye zemishini yezokwelapha ehlukahlukene, njengamathuluzi okuhlinza, amagobolondo edivayisi yezokwelapha, njll., ukuhlinzeka ngendlela ebalulekile yokukhiqiza embonini yemishini yezokwelapha.

Isikhombisa. Ukuthuthukiswa Kwekusasa leCNC Machining Center

Ngokuqhubeka okuqhubekayo kwesayensi nobuchwepheshe kanye nokuthuthuka okuqhubekayo kwemboni yokukhiqiza, izikhungo zemishini ye-CNC nazo zizoletha amathuba amasha entuthuko kanye nezinselelo. Nawa amathrendi entuthuko ezayo:

1. Ohlakaniphile: IkusasaCNC Machining Centerizohlakanipha kakhulu, ngokufunda okuzimele, ukulungisa okuguquguqukayo kanye neminye imisebenzi. Ngokusetshenziswa kobuchwepheshe bezobunhloli bokwenziwa, isikhungo somshini singathuthukisa ngokuzenzakalelayo imingcele yemishini nendlela yamathuluzi ngokuya nezici nezidingo zokucubungula ze-workpiece, futhi sithuthukise ukusebenza kahle kanye nekhwalithi yokucubungula.

2. Isivinini esikhulu: Ngokuthuthuka okuqhubekayo kwezidingo zemboni yokukhiqiza ukuze kusetshenziswe kahle ukukhiqiza, ukuthuthukiswa kwesivinini esikhulu sezikhungo zemishini ye-CNC kuzoba umkhuba ongenakugwenywa. Ngokuzayo, isikhungo somshini sizoba nesivinini esiphezulu sokuphotha, isivinini sokuphakelayo esisheshayo kanye nokusheshisa okukhulu ukuze kuzuzwe imisebenzi yemishini esebenza kahle kakhulu.

3. Inhlanganisela: Ukuze kuhlangatshezwane nezidingo zemboni yokukhiqiza yokucubungula imisebenzi eminingi, iCNC Machining Centerizothuthuka iye ohlangothini lwenhlanganisela. Isikhungo semishini yesikhathi esizayo sizohlanganisa imisebenzi ehlukahlukene yokucubungula, njengokujika, ukugaya, ukubhola, ukuthepha, njll., ukufeza izinhloso eziningi zomshini owodwa futhi kuthuthukiswe izinga lokusebenzisa nokusebenza kahle kokukhiqiza kwemishini.

4. Ukwenza luhlaza: Ngokuqhubeka nokuthuthukiswa kokuqwashisa ngemvelo, ukuthuthukiswa kohlazaCNC Machining izikhungoizophinde ibe umkhuba obalulekile esikhathini esizayo. Isikhungo sokucubungula sesikhathi esizayo sizosebenzisa ubuchwepheshe obuningi bokonga ugesi nobungane nemvelo ukuze kuncishiswe ukusetshenziswa kwamandla kanye nokungcoliswa kwemvelo.

5. Inethiwekhi: Ngokuthuthuka okuqhubekayo kobuchwepheshe bolwazi, ukuthuthukiswa kwenethiwekhi yeCNC Machining izikhungoizophinde ibe umkhuba obalulekile esikhathini esizayo. Isikhungo semishini esizayo sizokwazi ukuxhuma futhi sihlanganyele nezinye izinto zokusebenza nezinhlelo ngenethiwekhi, siqaphele ukuqapha okukude, ukuxilongwa kwamaphutha, ukudluliswa kwezinhlelo kanye neminye imisebenzi, futhi sithuthukise ukusebenza kahle nokuhlakanipha kokuphathwa kokukhiqiza.

VIII. Isiphetho

Njengomuntu othuthukileIthuluzi lomshini we-CNC, isikhungo semishini ye-CNC sidlala indima ebalulekile ekukhiqizeni kwesimanje. Inezici nezinzuzo eziyingqayizivele, ingakwazi ukubona ukusebenza kahle nokunembile kokucubungula, futhi inikeze izingxenye eziphezulu nemikhiqizo yezimboni ezihlukahlukene. Ngenqubekelaphambili eqhubekayo yesayensi nobuchwepheshe kanye nokuthuthuka okuqhubekayo kwemboni yokukhiqiza, isikhungo semishini ye-CNC sizoqhubeka nokusungula izinto ezintsha kanye nokwenza ngcono, sinikeze ukwesekwa okuqinile kwezobuchwepheshe ekuthuthukisweni kwemboni yokukhiqiza. Esikhathini esizayo,CNC Machining izikhungoizothuthukela ohlangothini lwezobunhloli, isivinini esikhulu, ukuhlanganisa, ukutshala izihlahla kanye nokuxhumanisa inethiwekhi, ibe negalelo elikhulu ekuguquleni nasekuthuthukiseni nasekuthuthukisweni kwezinga eliphezulu kwemboni yokukhiqiza.

Millingmachine@tajane.comLeli ikheli lama le-imeyili. Uma uyidinga, ungangithumelela i-imeyili. Ngilinde incwadi yakho eseShayina.